How to Evaluate the Cost-Performance Ratio of Dry-Type Transformers

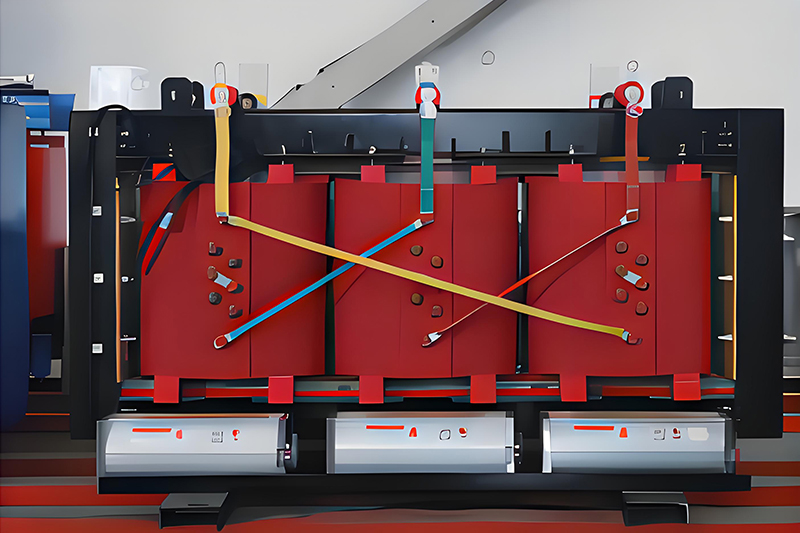

Choosing the right dry-type transformer is a critical decision that directly impacts system reliability, long-term operating costs, and energy efficiency. This article offers a practical guide to help procurement professionals and engineers compare transformers across key performance indicators, cost structures, and long-term value, ensuring smarter investment decisions.

Key Performance Factors to Compare

1. Technical Parameters

Rated Capacity and Voltage: Match the transformer’s capacity (e.g., 100kVA to 3150kVA) and voltage level (e.g., 10kV/0.4kV) with actual system demand. Oversized units increase capital cost, while undersized units may compromise system reliability.

Losses and Efficiency: Lower no-load and load losses mean higher energy efficiency. For instance, SCB14 transformers typically reduce energy losses by ~20% compared to SCB10 models, translating into substantial long-term electricity savings.

Insulation Class and Temperature Rise: Look for high thermal endurance (Class F or H) and temperature rise limits ≤100K. These factors indicate resilience under high ambient temperatures and load conditions.

Overload Capacity: Ensure the unit can operate under 1.5x rated load for at least 2 hours. This is essential for facilities experiencing periodic demand surges or fluctuating loads.

2. Reliability and Durability

Material and Process Quality: Epoxy resin cast transformers offer better short-circuit resistance than varnish-dipped types. Copper windings are preferred over aluminum for their better conductivity and durability.

Protection Rating: For harsh or outdoor environments, choose models with IP20 or above to prevent dust, moisture, and foreign object intrusion.

Certifications: Verify compliance with ISO 9001, CE, or CCC. Certified products meet stringent safety and quality benchmarks, reducing long-term risk.

Cost Structure Analysis

1. Initial Purchase Cost

Brand Premium: Global brands like ABB and Siemens typically charge 20–50% more than reliable domestic brands such as TBEA or Sunten. While international brands offer stability and innovation, domestic brands often deliver better cost-performance in standard applications.

Customization Fees: Non-standard configurations (e.g., special capacity, voltage combination, or casing type) may add 10–30% to the base price.

2. Operation and Maintenance Costs

Energy Efficiency Grade: Grade 1 transformers may save 5–8% more electricity annually than Grade 3. Over 10 years, this can result in power savings that exceed the upfront cost difference.

Maintenance: Models with sealed, maintenance-free designs minimize downtime and reduce the cost of parts and labor over time.

3. Total Cost of Ownership (TCO)

TCO Formula: TCO = Purchase Cost + Operating Cost (Electricity + Maintenance) – Residual Value

Example: A 1000kVA SCB14 transformer may cost 10% more than an SCB10 model but save up to 20,000 kWh per year. Over five years, the lower energy consumption makes it the more economical choice overall.

Evaluating Long-Term Value

1. After-Sales Support

Response Time: Local service networks that provide on-site support within 4 hours greatly reduce downtime and productivity loss.

Warranty Coverage: Opt for products with a 3 to 5-year warranty. This ensures protection against manufacturing defects and early-life failures.

Technical Services: Value-added support such as load monitoring, efficiency audits, and performance optimization enhances ROI over time.

2. Brand Reputation and Real-World Cases

Industry Use Cases: Brands with installations in mission-critical sectors (data centers, hospitals, transportation hubs) typically offer more refined product design and better quality assurance.

User Feedback: Check third-party reviews, bidding websites, or industry forums to identify brands with high reliability and low failure rates.

Strategic Procurement Recommendations

1. Application-Based Selection

High-Load Applications: Prioritize units with low losses and strong overload capacity—e.g., the SCB14 series from TBEA.

Cost-Sensitive Projects: Mid-tier domestic models like Sunten’s S11 series balance performance and cost for general applications.

Challenging Environments: For coastal, humid, or dusty conditions, select transformers with enhanced IP protection and corrosion-resistant coatings.

2. Supplier Negotiation Tactics

Bulk Discounts: For purchases of 5 units or more, request a 5–10% price reduction.

Service Terms: Negotiate extended warranties, on-site inspection packages, or annual maintenance services as part of the deal.

3. Risk Mitigation

Product Verification: Avoid ultra-low-priced or uncertified units. Inferior products may have failure rates over 30%, resulting in high long-term costs and safety risks.

Contract Clarity: Ensure the supplier commits to energy efficiency metrics and define penalties for quality or delivery failures.

Evaluating the cost-performance ratio of dry-type transformers goes beyond just price comparison. By considering technical performance, total cost of ownership, and supplier reliability, you can make informed decisions that deliver both immediate savings and long-term returns. Whether you’re equipping a smart grid, a hospital, or an industrial facility, selecting the right transformer is a strategic investment in your energy future.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri