How to Choose DDP Diamond Pattern Paper for Your Needs?

DDP diamond pattern paper is the core insulation material of electrical equipment such as power transformers and motors. Its performance plays a decisive role in the safety and reliability of equipment. Therefore, when purchasing, users need to comprehensively consider the application scenarios, process requirements, material characteristics, supplier qualifications, cost and delivery cycle.

1. Clarify the application scenarios and core requirements

Usage scenarios

Transformer coil insulation: When users use DDP diamond pattern paper for inter-turn and inter-layer insulation of transformers, the oil resistance, electrical insulation performance and mechanical strength of the material are key considerations.

High-voltage motors or electrical appliances: If users use it as an anti-corona layer or shielding material for high-voltage motors or electrical appliances, they need to focus on the breakdown voltage and corona resistance of the material.

Core requirements

Electrical insulation performance: Users must ensure that DDP paper can still maintain stable insulation performance under high temperature and high pressure environments.

Mechanical strength: After the material is cured, users must ensure that it has sufficient tensile and shear strength to prevent the winding from displacement during short circuit.

Oil resistance: For long-term use in an oil-immersed environment, the user should ensure that the material does not dissolve or soften.

2. Pay attention to the adaptability of materials and processes

Curing conditions

Curing temperature and time: Users need to ensure that the curing conditions of DDP diamond pattern paper match the production process. For example, the standard curing conditions are 90℃±5℃ for 3 hours and 125℃±5℃ for 6 hours. If the existing process cannot meet the requirements, users need to negotiate with suppliers to adjust the parameters.

Performance after curing: Users must ensure that DDP diamond pattern paper forms a stable insulation structure after curing and has excellent mechanical and electrical properties.

Construction process

Bond strength: Users need to ensure that the bonding strength of the glue paper under normal conditions meets the equipment requirements and ensures a strong bond between layers.

Operation convenience: Users should ensure that the cutting, winding and curing processes of the paper are compatible with the existing production line.

3. Pay attention to material storage and shelf life

Storage conditions

Environmental requirements: Users need to store DDP diamond pattern paper in a dry and clean indoor environment to avoid high temperature, fire and direct sunlight.

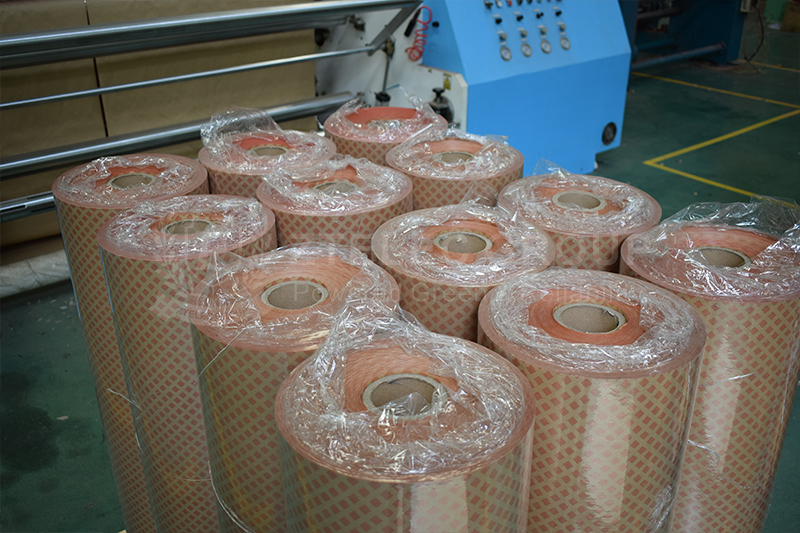

Packaging integrity: Users should ensure that the product packaging is intact to prevent moisture or contamination.

Shelf life management

Validity period: The standard storage period is one year. If the period is exceeded, the user must pass the inspection before use.

Inventory management: Users should purchase reasonably according to the production plan to avoid waste due to expiration.

4. Choose reliable suppliers and product certification

Supplier qualifications

Production capacity: Users should choose suppliers with stable production capacity and strong technical strength to ensure the consistency of product quality.

Service support: Users need to ensure that suppliers can provide technical support, after-sales guarantee, and have the ability to respond quickly.

Product certification

Test report: Users should require suppliers to provide third-party test reports to verify whether the material performance meets the standards.

Industry certification: Users can give priority to products certified by SGS, ISO, etc. to enhance quality credibility.

5. Balance cost and supply cycle

Price factor

Cost-effectiveness: On the premise of meeting performance requirements, users can choose reasonably priced products, and can also strive for discounts when purchasing in bulk.

Long-term cost: Users should avoid choosing inferior materials for the sake of low prices, which may lead to equipment failure or increase maintenance costs.

Supply cycle

Delivery capability: Users need to confirm the stability of the supplier's supply to avoid affecting the production progress due to out-of-stock.

Inventory strategy: Users can negotiate with suppliers to establish a safety inventory to reduce supply chain risks.

Every step in purchasing DDP diamond pattern paper is crucial, from clarifying needs to inspecting suppliers, from paying attention to process adaptability to balancing cost cycles, any negligence of details may affect the performance and life of the equipment. The above suggestions can help users make scientific and reasonable choices and build a reliable barrier for the safe and stable operation of electrical equipment.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri