How G11 Fiber Sheets Improve High-Temperature Electrical Insulation?

In the development of modern industry, electrical equipment in high-temperature environments has strict requirements on the performance of insulation materials. G11 fiber sheet has become the preferred material for high-temperature application scenarios due to its excellent high-temperature electrical insulation properties.

1.G11 fiber sheet material composition and process

Glass fiber and epoxy resin composite

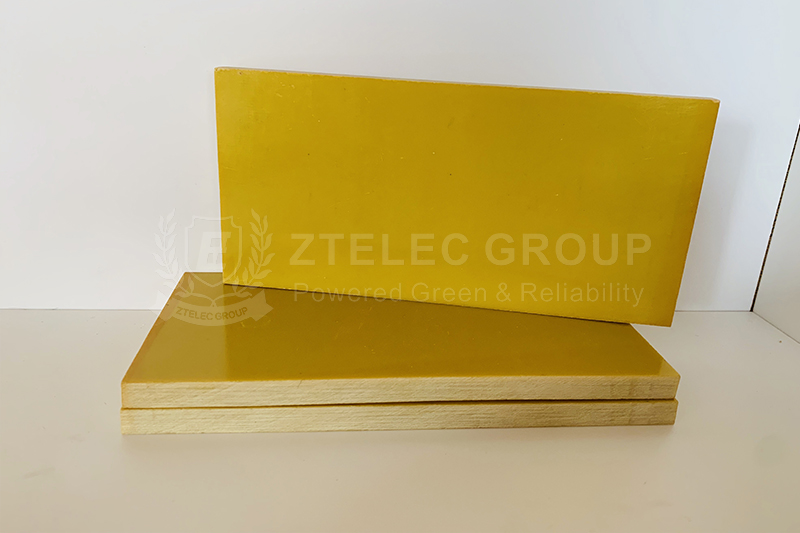

G11 fiber sheet is made of electrical alkali-free glass fiber cloth impregnated with epoxy resin and formed by high-temperature hot pressing. Electrical alkali-free glass fiber cloth has high strength and low dielectric constant, and epoxy resin has good adhesion and chemical stability. The two are combined to form a stable composite structure. This structure makes the mechanical strength of G11 fiber sheet stable at medium temperature, the dielectric properties are not greatly affected in high humidity environment, and it can still maintain high mechanical strength under high temperature conditions. Therefore, it is widely used in F-class motors, insulation structural components of electrical equipment, as well as electrical components around automobile engines, electrical equipment in industrial high-temperature furnaces and other mechanical or electrical parts in high-temperature environments.

High temperature resistant modification treatment

Researchers enhance the high temperature resistance of G11 fiber sheet by adding special additives or using special processes. Special additives react chemically with epoxy resin and glass fiber to optimize the molecular structure of the material to improve heat resistance. Some advanced modification processes can make the heat resistance temperature of G11 fiber sheet up to 330 degrees, far exceeding the heat resistance level of ordinary insulation materials, making it suitable for fields with strict high temperature requirements such as aerospace and new energy.

2.Process optimization

Decarbonization treatment

The decomposition of carbon-containing organic matter in glass fiber at high temperature will cause carbon atoms to precipitate, affecting the insulation performance, so decarbonization treatment is required. This treatment is carried out in a non-vacuum heating furnace, and the operator accurately controls the heating temperature and insulation time. Heating promotes the decomposition of carbon-containing organic matter, but too high a temperature will damage the mechanical strength and mechanical properties of glass fiber. After a large number of experiments, the appropriate temperature curve and insulation time are determined to ensure that the glass fiber achieves the target insulation performance while reducing the impact on its mechanical properties.

Gas exchange

During the insulation stage of decarbonization treatment, gas exchange in the furnace ensures the insulation performance of glass fiber. The composition of the gas in the furnace affects the performance of the glass fiber, and the oxygen content is the key factor. Maintaining the oxygen content in the furnace at least 5% can maintain the chemical stability of the glass fiber surface and avoid the oxidation-reduction reaction caused by lack of oxygen that damages the insulation performance. By regularly or in real time detecting the gas composition in the furnace and performing gas exchange as needed, the insulation performance of the glass fiber can be ensured to be stable during high-temperature treatment.

3.Structural design

Multi-layer composite structure

In scenarios where insulation performance requirements are extremely high, a multi-layer composite structure is used to improve the insulation effect of G11 fiber sheet. A buffer layer is added between the insulation layer and the conductive layer, and highly elastic silicone or polyurethane materials are selected. These materials relieve the stress caused by thermal expansion and contraction, prevent the insulation layer from being damaged, and reduce the risk of insulation failure.

Optimize line layout

Line layout optimization reduces the probability of insulation failure. Replan the circuit to reduce the exposed area of the insulation layer, centrally arrange sensitive circuit areas and increase the thickness of the insulation protection layer in this area. For example, in the design of the circuit board, the key signal transmission lines are concentrated and wrapped with thicker insulation materials on the periphery to reduce external interference with the circuit, improve insulation performance, and ensure the stable operation of electrical equipment in high temperature environments.

G11 fiber sheet has significant advantages in high-temperature electrical insulation performance due to its unique material composition and process, fine process optimization and innovative structural design, providing strong support for the safe and stable operation of electrical equipment in high temperature environments.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri