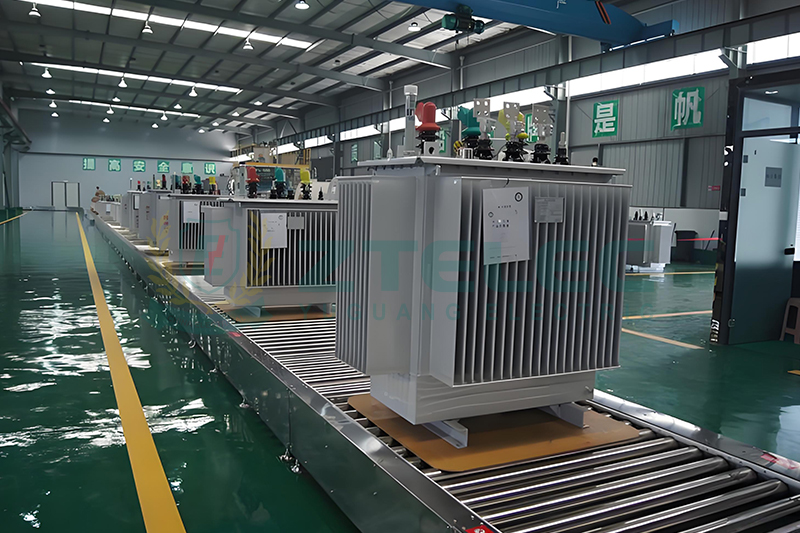

Oil-Immersed Transformer Production Line: Equipment, Process, and Quality Control

Oil-immersed transformers are widely applied in power transmission and distribution networks, industrial power systems, renewable energy projects, and large-scale infrastructure. Their advantages, including high reliability, long service life, excellent heat dissipation, and strong overload capacity, make them one of the most commonly used transformer types worldwide.

The overall performance of an oil-immersed transformer is directly determined by the manufacturing capability of the production line. This article provides a systematic introduction to an oil-immersed transformer production line from three core perspectives: production equipment configuration, manufacturing process flow, and quality control system. It aims to help engineering professionals and purchasers accurately evaluate transformer manufacturers and product quality.

Core Production Equipment for Oil-Immersed Transformers

Core Processing Equipment

The magnetic core is a critical component that directly affects transformer losses and operating efficiency. Advanced oil-immersed transformer production lines are equipped with high-precision silicon steel sheet slitting and cross-slitting lines. These CNC-controlled systems maintain dimensional tolerances within ±0.1 mm, ensuring consistency and minimizing magnetic flux deviation.

Fully automatic lamination workstations are used to complete stepped lap and oblique joint core stacking processes with high repeatability. After stacking, the core is treated in a controlled annealing furnace to improve permeability, reduce internal stress, and significantly lower no-load losses.

Winding Manufacturing Equipment

Winding accuracy and stability are essential for ensuring insulation performance and thermal balance. Vertical winding machines equipped with closed-loop tension control systems are commonly used for high-voltage and large-capacity transformer coils. These machines maintain stable conductor tension throughout the winding process, preventing deformation and insulation damage.

Horizontal winding machines are typically applied to small and medium-capacity transformers, featuring real-time monitoring of turns count and winding dimensions. Prior to winding, conductors undergo pretreatment processes such as deburring, straightening, and insulation coating to ensure smooth surfaces and consistent insulation thickness.

Insulation Treatment and Assembly Equipment

Moisture control is a decisive factor in transformer insulation reliability. Vacuum drying tanks are used to remove residual moisture from windings under high vacuum conditions, typically maintained below 0.1 mbar. This process effectively improves dielectric strength and long-term insulation stability.

Oil treatment systems employ multi-stage dehydration, degassing, and fine filtration to ensure that insulating oil meets strict electrical and cleanliness requirements. In advanced production lines, the breakdown voltage of treated oil reaches 70 kV or higher. Intelligent assembly platforms with laser alignment systems ensure precise positioning of cores and windings, reducing mechanical stress and assembly deviation.

Testing and Packaging Equipment

Fully automatic vacuum oil filling machines precisely control oil filling speed and vacuum level to prevent air entrapment. Transformer tanks are sealed using argon-shielded welding processes, which minimize oxidation and improve weld quality.

Online testing fixtures are integrated into the production line to perform essential electrical checks such as turns ratio measurement, winding resistance testing, and partial discharge monitoring before final inspection and shipment.

Oil-Immersed Transformer Manufacturing Process

A standardized oil-immersed transformer manufacturing process ensures consistency, reliability, and compliance with design specifications. The typical production workflow begins with core shearing and stacking, followed by high- and low-voltage winding fabrication. After winding completion, coils undergo drying and insulation treatment to eliminate moisture and enhance dielectric strength.

Subsequent stages include core and winding assembly, lead connection, insulation fixing, and comprehensive vacuum drying combined with vacuum oil filling. After tank assembly and sealing, the transformer proceeds to complete electrical testing and performance inspection. Finally, surface painting for corrosion protection and secure packaging are carried out before shipment.

Strict process control at each stage ensures that the transformer meets design requirements for insulation performance, temperature rise limits, electrical losses, and mechanical strength.

Quality Control System in Oil-Immersed Transformer Production Lines

Raw Material Quality Control

High-quality raw materials form the foundation of reliable transformer performance. Low-loss, high-permeability silicon steel sheets are selected to reduce energy losses. Enameled copper or aluminum conductors comply with international standards such as IEC and GB, ensuring electrical conductivity and insulation reliability. Insulating paper and boards are selected based on stable thermal class ratings and mechanical strength.

Process Quality Control

Quality inspection points are established at critical manufacturing stages. Key parameters such as winding dimensions, turns count, and tension are continuously monitored. Core stacking tolerances are inspected online to ensure magnetic circuit consistency and minimize vibration and noise.

Factory Testing and Inspection

Before delivery, each oil-immersed transformer must pass a complete set of routine and type tests. These include turns ratio verification to confirm winding accuracy, DC resistance testing to assess conductor connections, and no-load and load loss measurements to evaluate energy efficiency. Power frequency withstand voltage tests and partial discharge tests are conducted to verify insulation integrity and long-term operational reliability.

Certification and Standards Compliance

Mature oil-immersed transformer production lines typically operate under internationally recognized management systems, including ISO 9001 for quality management, ISO 14001 for environmental management, and ISO 45001 for occupational health and safety. Finished products comply with global standards such as IEC, ANSI, and GB, meeting the requirements of different regional markets.

Industry Trends and Technological Innovation

With the advancement of intelligent manufacturing, modern transformer production lines increasingly integrate machine vision systems to identify core lamination defects and dimensional deviations. Digital twin technology is applied to simulate winding temperature distribution and optimize thermal design. AI-based data analysis is also used to predict insulation aging and improve preventive maintenance strategies.

Green manufacturing has become another important development direction. Many manufacturers are upgrading production lines to support vegetable ester insulating oil, which offers improved environmental performance. Fully enclosed oil treatment systems are employed to reduce VOC emissions, while recycling technologies for waste silicon steel sheets are continuously improved to reduce material consumption.

The quality and reliability of oil-immersed transformers depend on the coordinated operation of advanced production equipment, standardized manufacturing processes, and rigorous quality control systems. By adopting precise process control, intelligent equipment, and comprehensive testing procedures, manufacturers can ensure stable transformer performance and long service life.

If you are looking for an oil-immersed transformer manufacturer with a complete production line and strict quality management system, please contact us for professional technical support and customized solutions.

- more+releated article

- 2026-01-14Oil-Immersed Transformer Production Line: Equi

- 2026-01-14High-Performance High-Density Electrical Lamin

- 2026-01-13Rising Resin Costs Put Pressure on the Semicon

- 2026-01-13Transformer Manufacturing Production Line Proc

- 2026-01-12A Specialized Manufacturer of Oil-Immersed Tra

- 2026-01-09Application Analysis of 11168kVA Oil-Immersed

- 2026-01-08Epoxy Pre-impregnated DMD vs. DMD: Key Differe

- 2026-01-08Why Oil Type Transformers Are Still a Core Com

- 2026-01-08Insulation Paper Production Cost and Profit An

- 2026-01-08How do the processing characteristics of DMD p