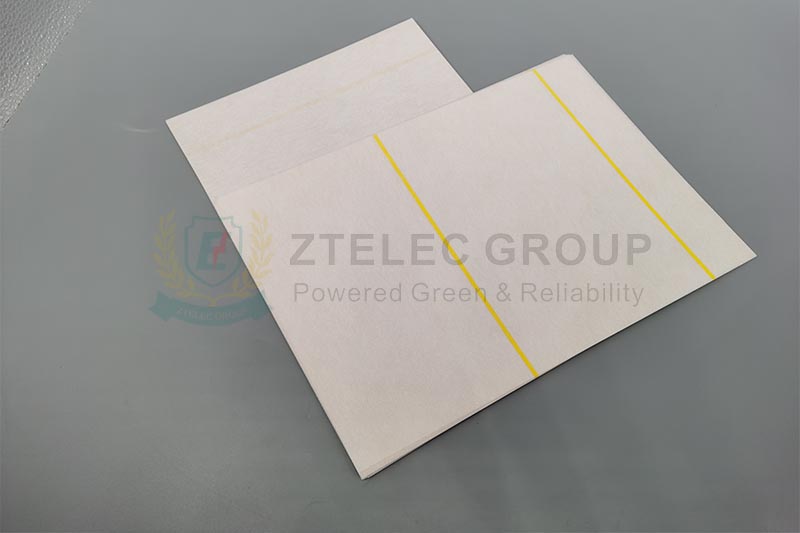

Class H Insulation Paper NMN Electrical Motor Winding

In the modern motor manufacturing industry, the winding insulation system is a crucial component for ensuring safe motor operation, maintaining stable performance, and extending service life. H-Class NMN insulating paper is a high-performance composite flexible insulating material with outstanding heat resistance, electrical insulation capabilities, and mechanical strength. It has become a commonly used material for high-end motor winding insulation, widely applied in industrial motors, new energy equipment, rail transit equipment, and export-oriented motor products.

Overview of H-Class NMN Insulating Paper

H-Class NMN insulating paper is an H-class (180℃) insulating material composed of NOMEX® aramid paper and polyester film. This material employs a three-layer composite structure:

The two outer layers are NOMEX aramid paper, possessing good mechanical toughness and heat resistance.

The middle layer is a polyester film, providing high dielectric strength and corona resistance.

This structure combines the performance characteristics of different substrates to form an effective insulating layer.

Key Performance Characteristics of H-Class NMN Insulation Paper

1.High Heat Resistance

As an H-class (180℃) insulation material, NMN insulation paper supports long-term operation of motors in high-temperature environments. This helps improve the thermal load capacity and overload margin of equipment, thereby extending the motor's service life.

2.Excellent Electrical Insulation Performance

The intermediate polyester film layer has high dielectric strength and insulation resistance. It resists high-voltage breakdown, arc discharge, and corona erosion, ensuring stable operation of the motor under high-voltage conditions.

3.Good Mechanical Strength and Flexibility

NOMEX® aramid paper gives the material high tensile strength, tear resistance, and flexibility. These properties make it easy to wrap, fold, and shape, and it is not easily damaged during production and use.

4.Chemical Stability and Environmental Friendliness

This material is resistant to most chemical solvents and has moisture-proof, mildew-resistant, and flame-retardant properties.

It is halogen-free, complies with RoHS and other environmental requirements, and is suitable for a variety of environments.

5.Long-term stable performance

Under conditions of continuous high temperature and vibration, NMN insulating paper can still maintain stable performance, avoid insulation layer aging, and reduce equipment maintenance costs.

Summary Table of H-Class NMN Insulating Paper Performance

|

Performance Item |

Performance Characteristics |

|

Insulation Class |

H-Class (180℃) |

|

Thermal Aging Resistance |

Stable performance under long-term high temperature |

|

Dielectric Strength |

High breakdown voltage |

|

Mechanical Strength |

Tear-resistant, fold-resistant |

|

Processing Performance |

Easy to cut, good formability |

|

Environmental Compliance |

Meets RoHS requirements |

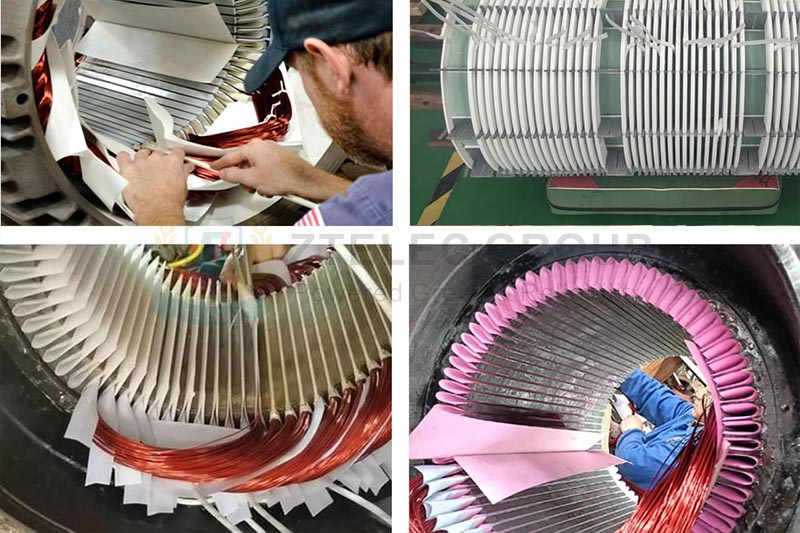

Applications of H-grade NMN Insulating Paper in Motors

Industrial Motors

Including high-voltage motors, explosion-proof motors, and variable frequency motors.

New Energy Motors

Such as drive motors for new energy vehicles, wind turbines, and energy storage system motors.

Rail Transit Motors

Mainly used in subway traction motors, high-speed train auxiliary motors, and other equipment.

Export Motors

Products comply with international standards such as IEC, UL, and EN, meeting the market access requirements of Europe, America, the Middle East, Southeast Asia, and Africa.

Selection Considerations for H-Class NMN Insulating Paper

The following technical parameters should be considered comprehensively when selecting:

Thickness and Basis Weight: Select appropriate specifications based on the motor voltage rating and slot space.

Raw Material Content and Type: The polyester film content affects the material's voltage resistance and corona resistance.

Adhesive System: The adhesive type determines the material's temperature resistance, bond strength, and flexibility.

International Standard Compliance: Products must comply with relevant standards such as IEC, UL, and NEMA, and possess complete certification reports.

Key Points for Installation and Processing of H-Class NMN Insulation Paper

To ensure the integrity of the motor insulation system, the following precautions should be taken when using NMN insulation paper:

♦ Keep the processing environment clean to avoid contaminating the insulation paper.

♦ Control the wrapping tension and layer flatness according to process requirements.

♦ During the impregnation or vacuum pressure impregnation process, ensure that the resin fully penetrates the interior of the insulation paper.

♦ Follow the processing technology and heat treatment specifications provided by the manufacturer.

As motors develop towards higher efficiency, higher power density, and higher reliability, winding schemes using H-class NMN insulation paper have become a common choice in the industry. Selecting high-quality NMN insulation materials is an important measure to ensure the quality of motor products and also has long-term significance for enhancing brand market competitiveness.

- more+releated article

- 2026-01-08Epoxy Pre-impregnated DMD vs. DMD: Key Differe

- 2026-01-08Why Oil Type Transformers Are Still a Core Com

- 2026-01-08Insulation Paper Production Cost and Profit An

- 2026-01-08How do the processing characteristics of DMD p

- 2026-01-08150KVA Three-Phase Dry-Type Isolation Transfor

- 2026-01-08Specific Applications of Glass Fiber Wound Tub

- 2026-01-08Why Data Centers Choose Three-Phase Isolation

- 2026-01-08G10 Glass Fiber Filament Winding Tube Standard

- 2026-01-08European Prefabricated Substation Design: Inte

- 2026-01-08Application of SMC Insulation Boards in Switch