product description

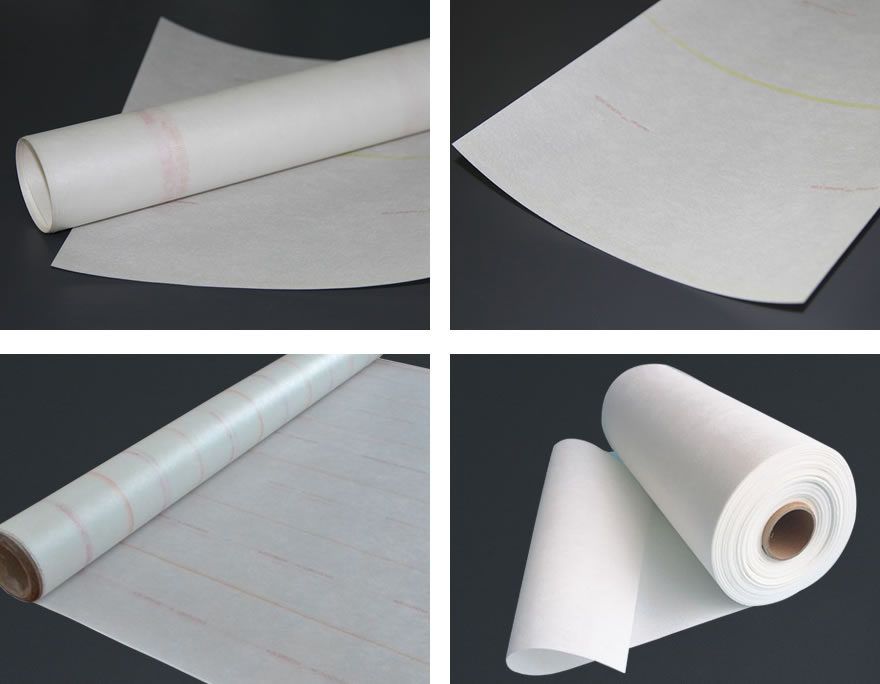

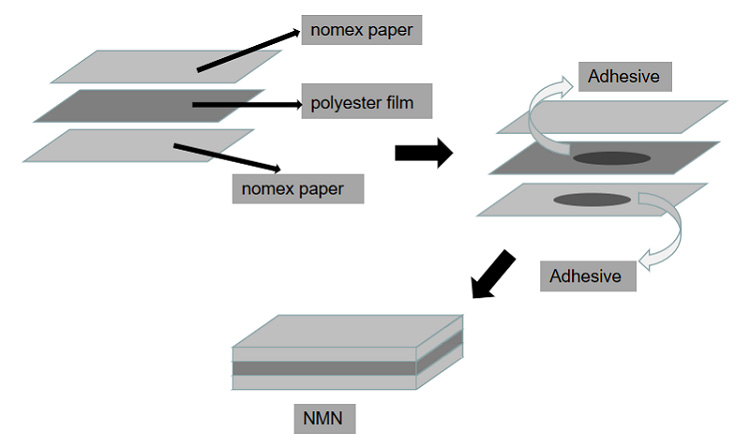

NMN 6640 NOMEX mylar paper is three- layer composite material with NOMEX paper adhered to both sides of polyester film.It has excellent heat resistance and tear resistance by its paper and good dielectric strength and mechanical strength by its film.

The product is used as insulation material for F/H class electrical machines.

NNM-Nomex-insulation-paper

NMN 6640 NOMEX mylar paper Material properties:

Type: Insulation composite material, Insulation Materials

Material: Nomex paper +Polyester Film+Nomex paper

Application: High Voltage

Thickness:0.10/0.13/0.15/0.18/0.20//0.22/0.25/0.30/0.35(mm)

Width: 980(mm)

nmn-composition

Nomex layer: high temperature resistance, flame retardant, high mechanical strength.

Polyester film layer: excellent electrical insulation performance and chemical resistance.

Thickness: Common thickness is 0.15mm to 0.35mm.

Heat resistance grade: F/H Class(155/180°C).

Electrical insulation performance: excellent, suitable for high frequency and high voltage environment.

Mechanical properties: good flexibility and strong tear resistance.

Flame retardant: Nomex layer provides good flame retardant properties.

NMN 6640 NOMEX mylar paper product parameters:

Comparison Table of NMN and NHN

| Standard:GB/T5591.3-2008 | NMN | NHN | NMN | NHN | NMN | NHN | NMN | NHN | NMN | NHN | NMN | NHN | ||

| Standard Thickness | mm | 0.15 | 0.17 | 0.2 | 0.25 | 0.3 | 0.35 | |||||||

| Thickness Tolerance | ±mm | 0.02 | 0.03 | |||||||||||

| Basic weight | g/m2 | 150 | 140 | 170 | 170 | 210 | 190 | 280 | 250 | 350 | 300 | 440 | 350 | |

| Tensile Strength | MD | N/10mm | ≥150 | ≥140 | ≥160 | ≥160 | ≥170 | ≥160 | ≥220 | ≥200 | ≥260 | ≥270 | ≥300 | ≥300 |

| MD After Bending | ≥80 | ≥70 | ≥90 | ≥90 | ≥100 | ≥90 | ≥130 | ≥160 | ≥200 | ≥140 | ≥180 | ≥180 | ||

| TD | ≥90 | ≥80 | ≥90 | ≥90 | ≥100 | ≥100 | ≥150 | ≥180 | ≥200 | ≥150 | ≥250 | ≥260 | ||

| TD After Bending | ≥70 | ≥50 | ≥70 | ≥70 | ≥90 | ≥60 | ≥120 | ≥100 | ≥150 | ≥90 | ≥180 | ≥130 | ||

| Elongation | MD | % | ≥15 | ≥15 | ≥15 | ≥17 | ≥15 | ≥15 | ≥20 | ≥17 | ≥20 | ≥15 | ≥20 | ≥17 |

| TD | ≥20 | ≥15 | ≥20 | ≥17 | ≥20 | ≥15 | ≥20 | ≥17 | ≥25 | ≥15 | ≥25 | ≥17 | ||

| Breakdown Voltage | No bending | KV | ≥7.0 | ≥7.0 | ≥8.0 | ≥9.0 | ≥11.0 | ≥10.0 | ≥13.0 | ≥10.0 | ≥15.0 | ≥10.0 | ≥20.0 | ≥10.0 |

| After Bending | ≥6.0 | ≥6.0 | ≥7.0 | ≥8.0 | ≥9.0 | ≥8.0 | ≥12.0 | ≥8.0 | ≥13.0 | ≥8.0 | ≥16.0 | ≥8.0 | ||

| Adhesion | As received | – | No Delamination | |||||||||||

| 180±2℃/10min | – | No Delaminating, Blister or Gummosis | ||||||||||||

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube