How to Identify a Dry-Type Transformer: Key Features and Applications?

In modern power systems, dry-type transformers are widely used in commercial buildings, industrial facilities, and infrastructure projects thanks to their oil-free operation, high safety, and environmental adaptability. Understanding dry-type transformer features is essential for correct selection, installation, maintenance, and ensuring reliable power system performance. Below is a detailed guide on identification methods based on appearance, nameplate markings, insulation materials, and application scenarios.

1. Appearance

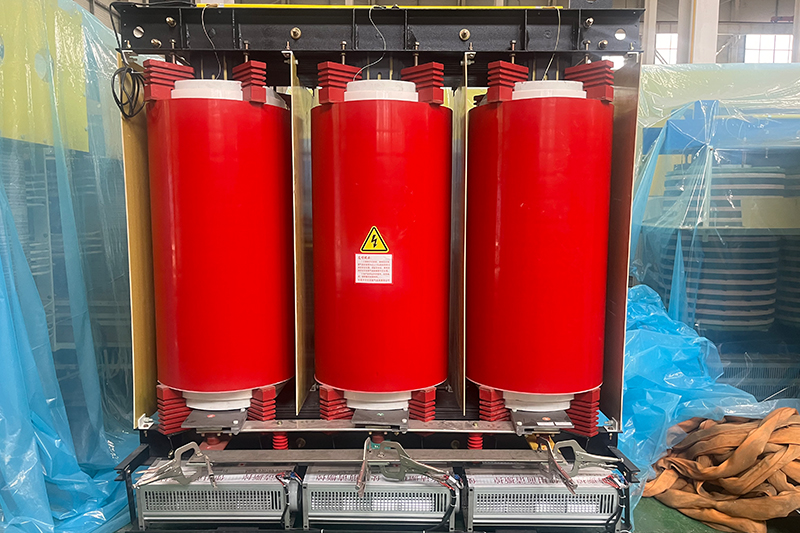

The most distinct dry-type transformer features are visible in its structure and design, which differ greatly from oil-immersed transformers:

No Oil Tank or Conservator: Dry-type transformers have no metal oil tank, oil conservator, oil level gauge, or cooling pipes, resulting in a more compact and lighter structure.

Winding Configuration: Open (non-encapsulated) designs feature exposed windings coated with insulating varnish or wrapped in Nomex paper, while epoxy-encapsulated designs completely seal windings in epoxy resin for improved dust and moisture resistance.

Heat Dissipation: Cooling relies on natural air (AN) or forced air (AF) with ventilation holes, heat sinks, or fins—unlike the tubular heat sinks in oil-immersed units.

2. Insulation Material

Dry-type transformers use air as the cooling medium. Windings and cores are exposed to air, with external insulation made from flame-retardant glass fiber-reinforced epoxy resin, offering high heat resistance and mechanical strength. This is in stark contrast to oil-immersed transformers, which immerse windings in transformer oil inside a large metal tank.

3. Nameplate and Labeling

The transformer nameplate provides critical identification details:

Model Codes: Domestic models often start with "SC" (e.g., SCB10, SCB13). "S" denotes three-phase, "C" indicates solid insulation (epoxy resin casting), "B" means foil winding, and "R" refers to copper wire winding. Imported models may include terms like “Dry-type” or “VPI” (Vacuum Pressure Impregnation).

Technical Data: Parameters such as rated capacity, voltage, current, insulation class (commonly F or H), and cooling method (AN or AF) confirm its type. A lack of oil immersion indicators further validates it as a dry-type transformer.

4. Typical Application Scenarios

Thanks to their oil-free, fireproof, and environmentally friendly nature, dry-type transformers are used in:

• Indoor power distribution for malls, hospitals, schools, and high-rise buildings.

• Enclosed or hazardous locations such as subways, tunnels, and mines.

• High-cleanliness environments like data centers, laboratories, and precision manufacturing facilities.

5. Common Dry-Type Transformer Types

Epoxy-Cast (SCB Series): Fully encapsulated in epoxy resin for superior dust and moisture resistance, suitable for humid or dusty sites.

Open Type (SG Series): Varnish-coated windings without full sealing, ideal for clean, dry indoor power rooms.

Amorphous Alloy (SCBH Series): Extremely low no-load losses for energy efficiency, perfect for green buildings and data centers.

By examining structural design, insulation materials, nameplate parameters, and installation environment, you can accurately identify a dry-type transformer and understand its unique operational advantages. Recognizing these dry-type transformer features ensures optimal selection, safe operation, and reliable maintenance in diverse power system applications.

- more+releated article

- 2025-10-21Application of K Factor Transformer

- 2025-10-21Detailed explanation about transformer model w

- 2025-10-2010kV Oil-Immersed Transformer Safety: Lightnin

- 2025-10-20What are The Advantages of Phenolic Cotton Clo

- 2025-10-17Are Three-Phase Isolation Dry-Type Transformer

- 2025-10-17G10 Epoxy Sheet: Choosing the Right Specificat

- 2025-10-1610kV Oil-Immersed Transformer Operation Inspec

- 2025-10-163240-B Epoxy Phenolic Glass Fiber Cloth Lamina

- 2025-10-15G10 Epoxy Sheet: The Preferred Insulation Mate

- 2025-10-15Analysis of Energy-Saving and Noise Control Te