How to Scientifically Select High-Precision G10 Parts?

In precision manufacturing, the quality of G10 parts directly impacts equipment performance and service life. Selecting high-precision G10 parts requires a comprehensive evaluation of multiple factors, including material properties, process control, and supplier capabilities. The following is a systematic selection guide:

Identify G10 Material Properties

As a glass fiber-reinforced epoxy resin composite material, G10's core performance advantages determine its application scenarios:

Mechanical Properties: Excellent tensile strength and surface wear resistance make it suitable for load-bearing structural components.

Environmental Adaptability: Extremely low water absorption, maintaining stable dimensional accuracy in humid environments.

Electrical Properties: Excellent insulation properties, making it an ideal insulating material for electronic devices.

Chemical Stability: Good resistance to most acidic, alkaline, and organic solvents.

Thermal Properties: Low thermal expansion coefficient, maintaining dimensional stability over a wide temperature range.

Key Selection Points: Verify the compatibility of properties based on the application scenario—the aerospace industry prioritizes mechanical stability, while electronic equipment focuses on insulation performance. Medical devices also require additional verification of biocompatibility.

Key Precision Indicators

The core quality parameters of high-precision G10 machined parts must be precisely defined in the drawings:

Dimensional tolerance: Typically within ±0.05mm (to be marked according to the drawing).

Flatness/Parallelism: ≤0.1mm/m for precision parts.

Surface roughness: Ra ≤1.6μm (polishing or fine milling required).

Hole position accuracy: Positioning accuracy ±0.02mm (CNC machining required).

Safeguards:

Provide detailed engineering drawings with GD&T annotations and clearly define key characteristics (KPCs).

Jointly review process feasibility with suppliers to confirm the suitability of processes such as wire-cutting and precision engraving.

Key Points for Supplier Screening

High-quality suppliers are crucial for ensuring precision, and four key aspects should be considered when selecting suppliers:

Qualifications and Certifications: Prioritize companies with ISO 9001 quality management system certification; AS9100 certification is required for the aerospace sector, and FDA registration is required for the medical sector.

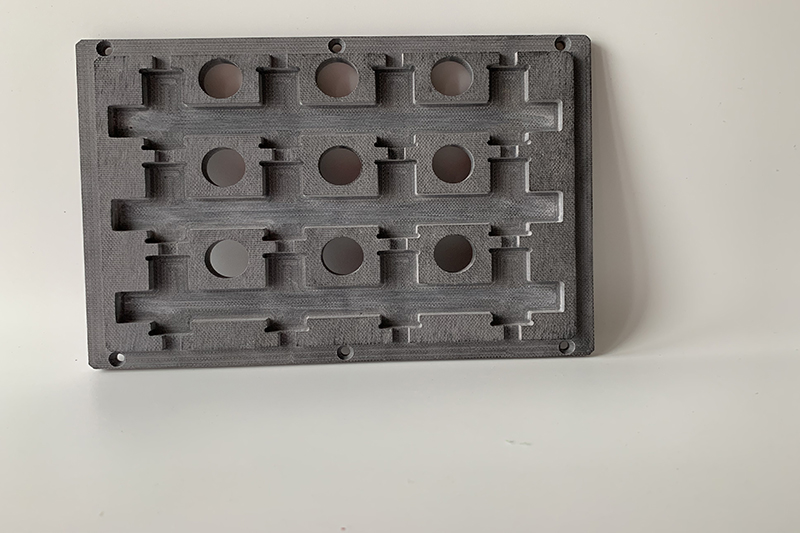

Equipment Capabilities: Verify the availability of high-precision processing equipment and specialized testing equipment, such as high-precision CNC machining centers and laser scanners.

Industry Experience: Require case studies from the same industry, such as precision components for semiconductor equipment and radar insulation brackets, with a focus on the ability to process complex structures.

Quality Control: Request a complete inspection report chain, including raw material certification, compliance reports, first-article inspection reports, and process capability analysis reports.

Processing Requirements

The particularity of G10 material imposes strict requirements on the processing technology:

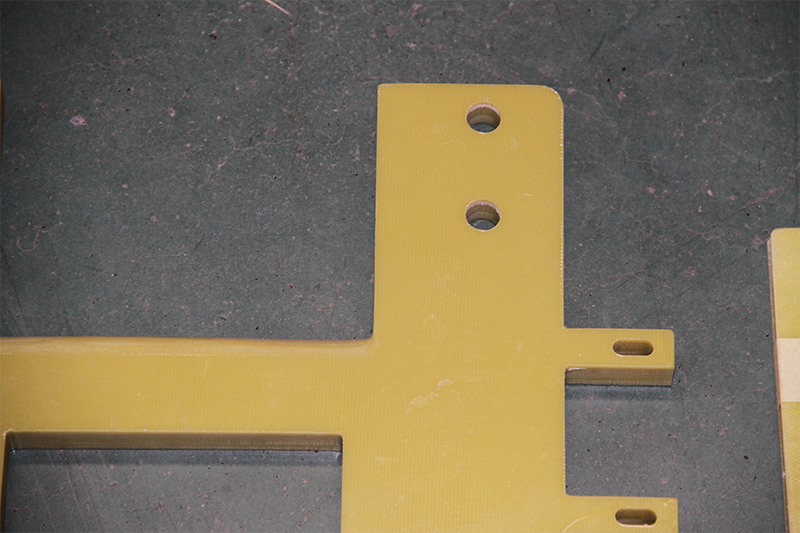

Tool Selection: Use ultra-fine-grain carbide or polycrystalline diamond tools, with a well-designed cutting edge to minimize fiber breakage.

Cutting Parameters: Maintain appropriate linear speed, feed rate, and depth of cut to prevent overheating and carbonization of the epoxy resin.

Post-Processing: Professional deburring is required, and moisture-proofing is required for use in humid environments.

Environmental Control: The machining workshop must maintain a constant temperature and humidity to minimize dimensional fluctuations caused by temperature changes.

Balancing Cost and Delivery Time

Maximizing Benefits While Ensuring Precision:

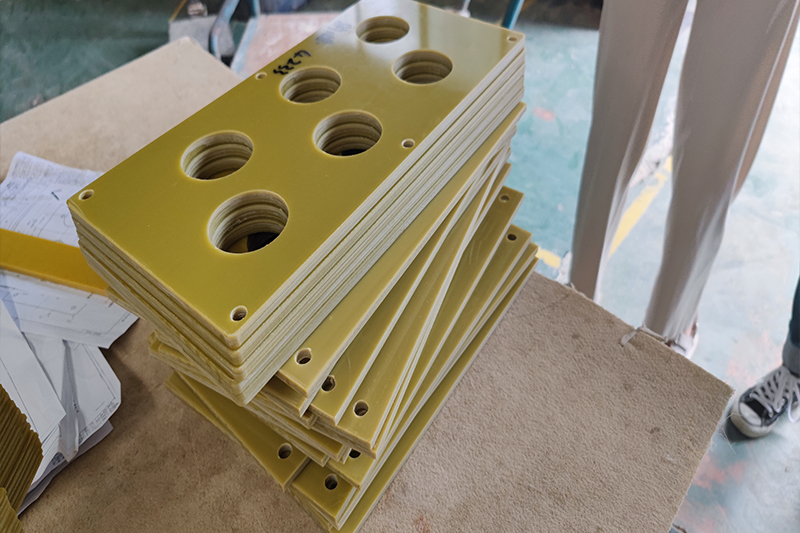

Batch Strategy: For small batches, rapid prototyping combined with precision machining can be employed; for large batches, dedicated fixtures are recommended to reduce unit costs.

Material Alternative Evaluation: If operating temperature requirements are not high, FR4 can be a low-cost alternative; if high-temperature resistance is required, G11 can be considered.

Delivery Time Control: Plan delivery time appropriately based on precision requirements. For ultra-high-precision parts, allow sufficient production and inspection time.

Common Problem Avoidance

Preventative Measures for Common G10 Machining Issues:

1. All cut surfaces must be edge-sealed with epoxy resin to enhance the bond between the fiber and the resin.

2. Avoid designing thin, long strips. Ribs are recommended for improved stability.

3. Military products require additional specialized material certification, and food contact components must obtain relevant food contact safety certification.

4. Establish clear acceptance criteria, conduct full inspections for critical dimensions, and conduct sampling inspections of non-critical dimensions at a reasonable ratio.

Through this systematic selection approach, the precision, stability, and reliability of G10 machined parts can be effectively guaranteed, mitigating future operational risks. It is recommended to conduct a small-batch trial production verification before mass production to comprehensively evaluate the matching degree between the processing quality and the actual working conditions.

- more+releated article

- 2025-10-21Application of K Factor Transformer

- 2025-10-21Detailed explanation about transformer model w

- 2025-10-2010kV Oil-Immersed Transformer Safety: Lightnin

- 2025-10-20What are The Advantages of Phenolic Cotton Clo

- 2025-10-17Are Three-Phase Isolation Dry-Type Transformer

- 2025-10-17G10 Epoxy Sheet: Choosing the Right Specificat

- 2025-10-1610kV Oil-Immersed Transformer Operation Inspec

- 2025-10-163240-B Epoxy Phenolic Glass Fiber Cloth Lamina

- 2025-10-15G10 Epoxy Sheet: The Preferred Insulation Mate

- 2025-10-15Analysis of Energy-Saving and Noise Control Te