What's the difference between GPO-3 and FR4?

GPO-3 sheet and FR-4 epoxy sheets are two core materials in the electrical insulation field. While they share some commonalities, their fundamental differences in material quality lead to significant differences in performance and application scenarios. Simply put, GPO-3 is a composite material based on unsaturated polyester resin, while FR-4 is a composite material based on epoxy resin. This fundamental difference directly determines their properties and application scope. Below, we will provide a detailed comparison from multiple perspectives.

Material Composition and Manufacturing Process

GPO-3 is reinforced with alkali-free glass fiber mat, impregnated with unsaturated polyester resin, and then formed through a high-temperature, high-pressure, heat-curing "lamination" process. Its structure is highly homogeneous and isotropic (i.e., the material's properties are essentially consistent in all directions).

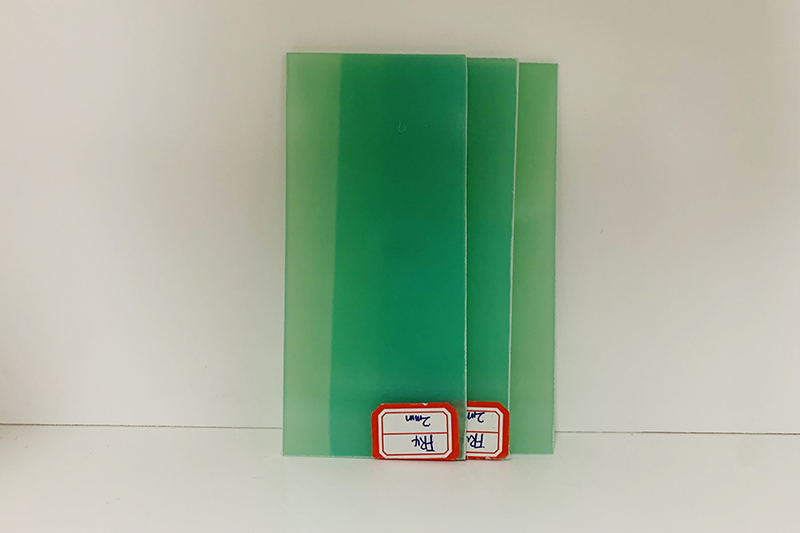

FR-4 is reinforced with electronic-grade glass fiber cloth, impregnated with brominated epoxy resin (bromine is added primarily to enhance flame retardancy), and then heat-cured at high temperatures and high pressures. Due to the woven structure of the glass fiber cloth, the material is directional, and the longitudinal and transverse strength performance is more prominent.

Key Performance Differences

1. Electrical Performance

Arc Resistance and Tracking Resistance (CTI):

This is GPO-3's core advantage. Its unsaturated polyester resin system results in extremely slow surface carbonization in high-voltage arc environments, effectively preventing arc propagation and the formation of conductive paths. Therefore, it excels in arc extinguishing applications.

FR-4 exhibits excellent arc resistance, but its overall performance is generally slightly inferior to that of GPO-3.

Insulation Performance:

Both are excellent insulating materials, but their properties differ. FR-4 offers superior moisture resistance (extremely low water absorption), maintaining stable insulation resistance and dielectric strength in humid environments, making it suitable for high-humidity applications.

GPO-3 offers stable insulation performance, but its moisture resistance is slightly weaker than that of FR-4.

2. Mechanical Performance

Strength and Toughness:

Thanks to its glass fiber fabric structure, FR-4 possesses extremely high mechanical strength, rigidity, and toughness. It can serve both as an insulator and as a structural component providing mechanical support. Its overall mechanical properties are far superior to those of GPO-3. Because GPO-3 uses glass fiber mat, it has lower mechanical strength and is relatively brittle, making it more susceptible to breakage when subjected to external impact.

Processability:

Both materials support machining processes such as drilling, milling, shearing, and punching, but each has its own unique characteristics. GPO-3's homogeneous structure results in smoother edges after machining, less prone to burrs, making it more suitable for machining small parts requiring high precision.

During FR-4 machining, pay special attention to the impact of fiber orientation on edge smoothness, but overall, its adaptability remains relatively strong.

Typical Application Scenarios

1.GPO-3 Applications

Electrical insulation components: Such as switchgear partitions, transformer supports, and busbar insulation clamps, capable of withstanding mechanical shock and medium voltage environments (≤10kV).

Railway: Electrical enclosures and connector insulators for subways and high-speed trains, relying on their impact resistance and environmental stability.

New Energy: Internal insulation supports for wind power converters and photovoltaic inverters, capable of withstanding harsh outdoor conditions such as high temperature and high humidity.

2.FR-4 Applications

Printed circuit boards (PCBs): These materials account for over 90% of the global PCB substrate market and are widely used in high-frequency, high-speed signal transmission applications such as computers, communications equipment, and consumer electronics.

High-voltage insulation components: Such as motor slot wedges and high-voltage switch insulators, with their high insulation resistance and stable arc resistance.

Precision mechanical components: Such as gears and bearing retainers, suitable for mechanical transmission applications requiring high strength and low friction. The differences between GPO-3 and FR4 stem primarily from their different resin base materials and reinforcement materials. GPO-3, known for its excellent arc resistance and smooth processing, is suitable for medium-voltage insulation and harsh environments. FR-4, on the other hand, is the preferred choice for PCB substrates and high-strength structural insulation components due to its high strength, toughness, and moisture resistance. In actual applications, the selection of the right material should be based on a comprehensive consideration of voltage level, mechanical strength requirements, and environmental conditions.

- more+releated article

- 2025-10-21Application of K Factor Transformer

- 2025-10-21Detailed explanation about transformer model w

- 2025-10-2010kV Oil-Immersed Transformer Safety: Lightnin

- 2025-10-20What are The Advantages of Phenolic Cotton Clo

- 2025-10-17Are Three-Phase Isolation Dry-Type Transformer

- 2025-10-17G10 Epoxy Sheet: Choosing the Right Specificat

- 2025-10-1610kV Oil-Immersed Transformer Operation Inspec

- 2025-10-163240-B Epoxy Phenolic Glass Fiber Cloth Lamina

- 2025-10-15G10 Epoxy Sheet: The Preferred Insulation Mate

- 2025-10-15Analysis of Energy-Saving and Noise Control Te