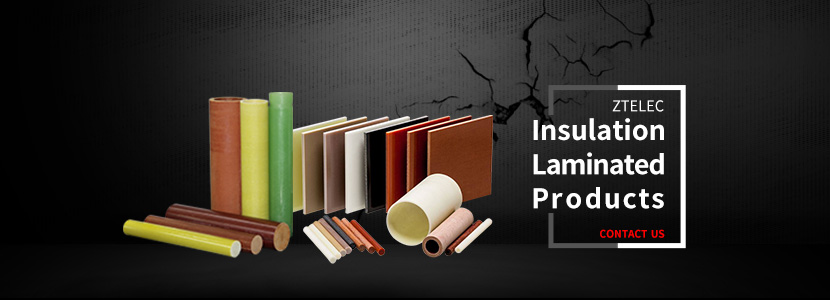

1. Phenolic paper laminated tube 3520

This product has good mechanical and electrical properties. It can be used for motor and electrical equipment and also can be used in transformer oil.

2. Phenolic cotton laminated tube 380/380A

The product has higher radial tensile strength. It can be used as support structure and wear-resistance parts of seals or bears.

3. EPGC21/22、355、356、SIGC21、BMIGC21

With good dielectric property and machinability, the product can be used as components of insulation structural of electrical equipment, and can also be made into coil insulation tube and insulation end coil of dry-type transformer.

Technical Data

Product Specification

This product has good mechanical and electrical properties. It can be used for motor and electrical equipment and also can be used in transformer oil.

2. Phenolic cotton laminated tube 380/380A

The product has higher radial tensile strength. It can be used as support structure and wear-resistance parts of seals or bears.

3. EPGC21/22、355、356、SIGC21、BMIGC21

With good dielectric property and machinability, the product can be used as components of insulation structural of electrical equipment, and can also be made into coil insulation tube and insulation end coil of dry-type transformer.

Technical Data

| Standards | GB/T 5132.1-2009 IEC61212-1:2006 | ||||||||

| Chinese Name | 3520 | 380 | 380A | 3640/3641 | 355 | 356 | 3652 | 364 | |

| IEC | PFCP22 | PFCC21 | PFCC24 | EPGC21/22 | - | - | SIGC21 | BMIGC21 | |

| NEMA | - | - | - | - | - | - | - | - | |

| Base Material | Paper | Cloth | Fiber Glass Cloth | ||||||

| Resin | Phenolic | Epoxy | Diphenyl Ether | Polyetherimide | Organic Silicone | Polyamide-imide | |||

| Color | Brown | Yellow | Dark Brown | White | White | Dark Brown | |||

| Properties | Unit | Value | |||||||

| Density | g/m³ | 1.0-1.1 | 1.2-1.3 | 1.7-1.8 | 1.7-1.8 | 1.7-1.8 | 1.7-1.8 | 1.7-1.8 | |

| Vertical Bending Strength (normal) | MPa | ≥90 | ≥138 | ≥150 | ≥70 | ≥80 | ≥80 | ≥80 | ≥80 |

| Axial Compressive Strength | MPa | ≥60 | ≥118 | ≥118 | ≥60 | ≥70 | ≥70 | ≥70 | ≥70 |

| Parallel BreakdownVoltage (90 ℃ transformer oil) |

KV | ≥25 | - | - | ≥35 | ≥25 | ≥25 | ≥25 | ≥25 |

| Vertical Electrical Strength (90 ℃ transformer oil) | KV/mm | ≥8 | ≥3.5 | ≥3.5 | ≥6-14① | ||||

| (wall thickness: 3.0mm inner diameter: 20mm) | |||||||||

| Dielectric Loss Factor(50Hz) | - | ≤0.03 | - | - | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.03 |

| Water Absorption | % | ≤8(3mm) | ≤5(3mm) | ≤4(3mm) | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| Temperature Index | - | 120 | 120 | 120 | 130/155 | 180 | 180 | 180 | 180 |

Product Specification

| Product Specification | 3520 | 380/380A | 3640/3641 | 355 | 356 | 3652 | 364 | 360 |

| PFCP22 | PFCC21/24 | EPGC21/22 | - | - | SIGC21 | BMIGC21 | EPCF52 | |

| Min Wall Thickness(mm) | 2.0 | 3.0 | ||||||

| Max Wall Thickness(mm) | 80 | 200 | 200 | 200 | 200 | 200 | 200 | - |

| Min Inside Diameter (mm) | 10 | 10 | 6 | 6 | 6 | 10 | 10 | 30 |

| Max Inside Diamete※(mm) | 1200 | 600 | ||||||

| Length(mm) | 1000 | 1000/1200 | 1000-3000 | |||||

.png)

.png)

.png)