product description

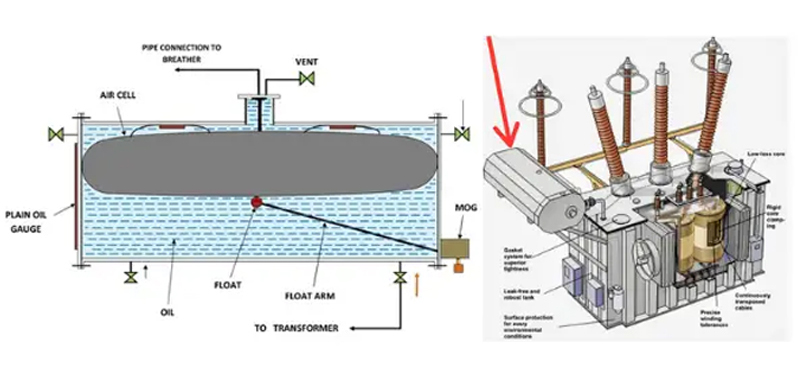

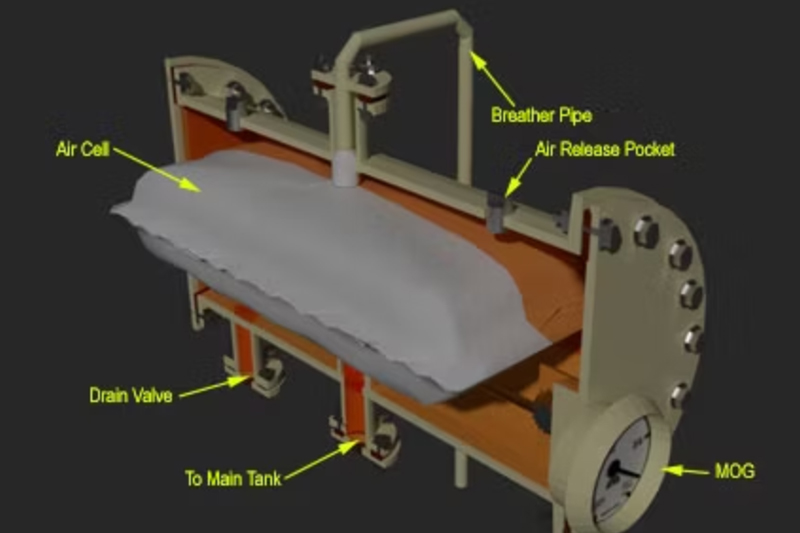

ZTELEC Diaphragm (Diaphragm Conservator) is fitted inside a conservator tank, isolating insulating oil from the atmosphere, and thus preventing contamination of gas and/or moisture from coming into contact with the transformer oil due to oxidation and hydrolysis. The bag is vented on the transformer through flange type mounting such that it inflates or deflates to accommodate oil volume displacements due to changes in the transformer temperature.

ZTELEC Diaphragm are manufactured using time tested Nitrile Rubber Coated Nylon Fabric and a thick coating of Elastomers i.e. Acrylonitrile Butadiene Rubber (NBR), Polychloroprene (CR) and Hypalon (CSM). The rubber compounds are so formulated, so as to minimize separator degradation and resist leakage of air through membranes thus reducing the amount of air in the transformer oil. Over a period of time this air/gases can reduce dielectric strength and thereby accelerate the aging of the insulation system.

Diaphragm parameters

Cell material: Nitrile Rubber / Coated Nylon Fabric

Air valve material: NBR / brass / customized rubber

Cell color: Black / Green / Blue / customized

Level gauge fitting: NBR / brass / customized rubber

Finishes: NBR / Smooth surface / Clean-free-surface

Shape: D type, capsule type, bag type or customized

Sizes and dimensions: as per customer requirement

Material properties

Characteristics to define behavior under various conditions and influences as per applicable standard

test procedures and guidance.

Reference standard: GB/T 5453-1997, GB/T1038.1-2022

Material thickness (mm): 0.7 – 1.0

Breathability: 24.5kPa x 3 min

Gas tightness:

|

Tightness (time/pressure) |

Static pressure (psi/ kPa) |

Component |

|

20 min |

(0.145) 1.0 |

no detectable leakage |

Hardness Scale: Shore A 60-65

Permeability (air as medium): 0.1Lit. (100 cubic cent) per 24 hr. standard

Material elongation: 15-20%

High temp resistance: up to 100℃

Low temp resistance and endurance: up to -40 ℃ tested at 2 hr. rate

Vol. change at 100℃ for 24 hours: 0% rate

Mechanical properties

Reference standard: HG/T 2580-2008 tensile force and GB/T 528-2009 tensile strength

Withstand forces such stretching or pulling force without fracturing.

|

Strength (kg) |

Longitudinal (N) (Lbf) |

Latitudinal (N) (Lbf) |

|

greater than 20 |

greater than 2000 |

greater than 2000 |

Adherent properties

Consists of elastic polymers, natural rubber and dissolved solution for bonding components

|

Adhesive strength (overlap shear / peel) (N)(kg) |

Bonding strength (overlap shear/peel) (N)(kg) |

|

greater than 200 using 50mm width strip |

greater than 2000 |

Oil contact

Reference standard: GB/T 16929-1997

Internal liquid temp resistance (oil as medium): up to 70℃

|

Oil permeability (g/m²·d) |

Regulator limit (g/m²·d) |

|

0 – 8.6 |

20 |

|

Liquid resistance (oil) |

|

|

70 ℃ |

|

Advantages of ZTELEC Diaphragm

· Simple design with no expandable parts.

· Sizes and dimensions: as per customer requirement

· Shape: D type, capsule type, bag type or customized

· Needs negligible man hours for inspection.

· Extended service life.

· Economical.

· Prevents corrosion.

· Oil can be filled into the transformer tank without being exposed to the air

· Since insulating oil is completely isolated from the atmosphere by an air cell, there is no possibility of oxygen or moisture penetrating the oil.

· Pressure on the surface of the oil is constantly maintained at the atmospheric pressure, offering no possibility of the oil becoming supersaturated and forming bubbles; thus, high dielectric strength can be maintained.

· Test reference:

HG/T 2580-2008 tensile force for rubber and plastic coated fabrics

GB/T 5453-1997 permeability of fabrics and volume of air flow per unit area

GB/T 531. 1-2008 hardness for rubber vulcanized and thermoplastics

GB/T 528-2009 tensile strength for vulcanized and thermoplastic rubbers

HG/T 2581. 1-2009 tear resistance for rubber and plastic coated fabrics

GB/T 3512-2014 thermal aging for rubber vulcanized and thermoplastics

GB/T 31547-2023 air tightness inner tubes

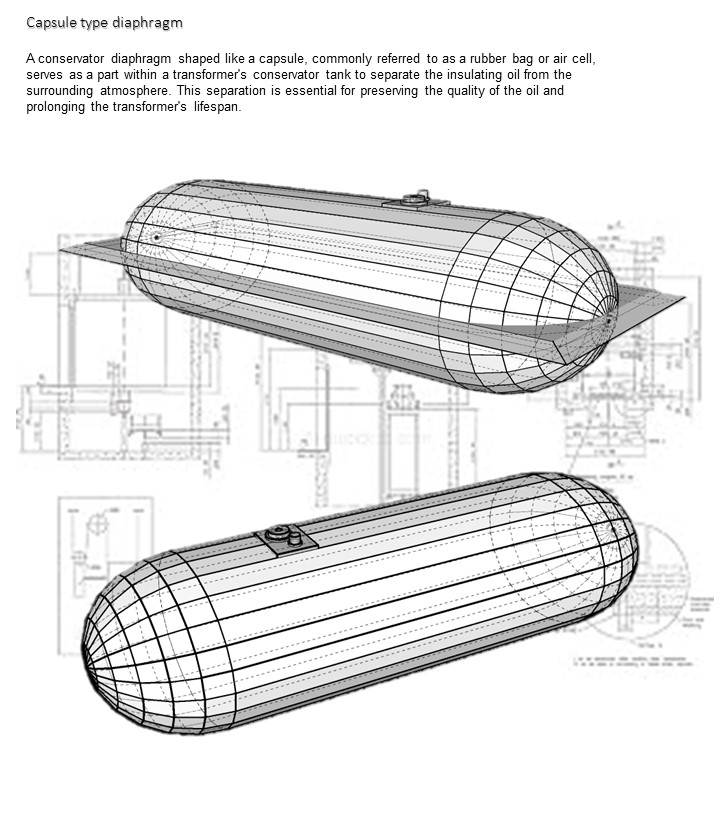

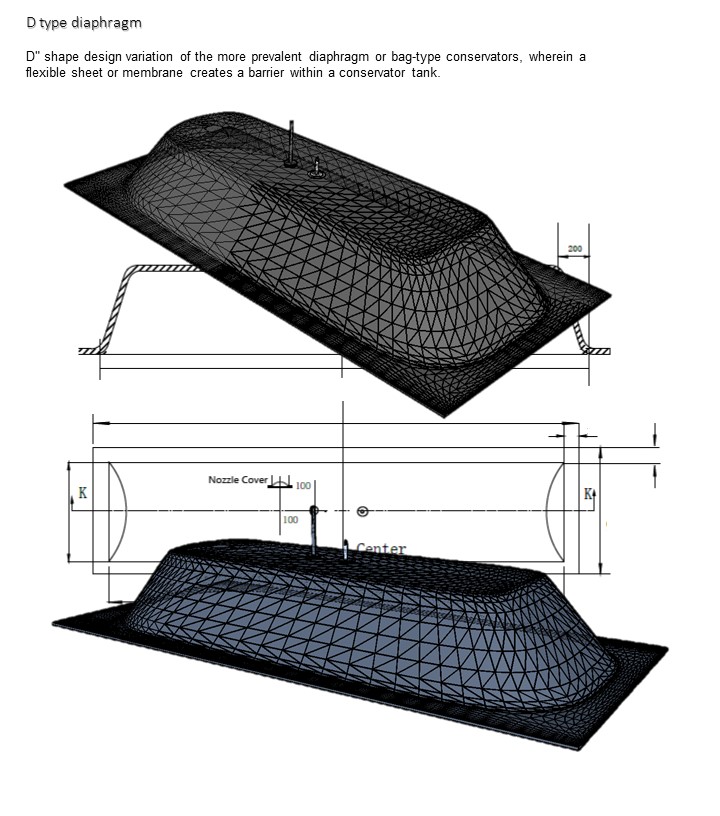

Customization according to conservator shapes and design

· Full application of customer requirement

· Air Cell / Diaphragm technical drawings and specification