Fr4 epoxy sheet processing from material to finished product

With the continuous development of science and technology, FR4 epoxy sheet, as a high-performance electronic material, has been widely used in various fields. However, to achieve the best performance of FR4 epoxy sheet, the processing link is crucial. This article will explore the processing process in depth to help readers better understand this key link.

First, let us understand the basic composition of fr4 epoxy sheet processing. It is a material composited with glass fiber and epoxy resin, which has good insulation properties, mechanical strength and heat resistance. During the processing, the raw materials need to undergo a series of treatments and processing to obtain the desired shape and performance.

FR4 epoxy sheet processing process

The first step in fr4 epoxy sheet processing is to prepare the raw materials. This includes steps such as mixing, stirring and impregnating glass fiber and epoxy resin to ensure the quality and stability of the raw materials. In this process, parameters such as temperature, time and stirring speed need to be precisely controlled to ensure the uniformity and consistency of the material.

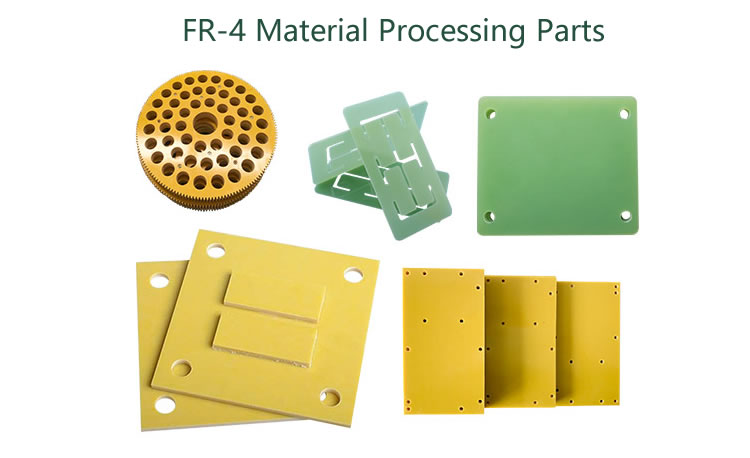

Next is the molding stage. At this stage, it is processed into the desired shape and size. This usually involves a variety of processes such as hot press molding, cold press molding, and injection molding. During the molding process, it is necessary to ensure that the parameters such as material density, thickness and dimensional accuracy meet the requirements to ensure the performance and quality of the finished product.

In addition to molding, FR4 epoxy sheet processing also includes subsequent processing such as drilling, cutting, and grinding. These steps are essential to meet the needs of different applications. For example, drilling can provide channels for conducting lines or installing electronic components; cutting can process large pieces of board into specific small pieces; grinding can improve the surface finish and flatness.

Finally, FR4 epoxy sheets need to undergo a series of inspections and tests to ensure that their performance and quality meet the requirements. This includes electrical performance tests, mechanical performance tests, environmental adaptability tests, etc. Only FR4 epoxy sheets that have been fully inspected and meet the requirements can be identified as qualified products for the manufacture of various electronic equipment and systems.

In general, FR4 epoxy sheet processing is a complex and delicate process that requires strict control of various process parameters and processing links. By deeply understanding the processing process, we can better understand its performance and application, and at the same time provide valuable reference for optimizing processing technology and improving product quality.

ZTelec Group is a professional manufacturer of high-quality electrical insulation materials, integrating the research and development, production and sales of electrical and electrical insulation materials. It has more than 60 years of manufacturing experience. The production capacity and market share of insulation materials are ranked top three in the industry, and special insulation materials are ranked first.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri