3240 Epoxy Board: Performance, Applications, and Future Trends

The 3240 epoxy board, as a high-performance material, is widely used across multiple industries due to its excellent physical and chemical properties. It features outstanding electrical insulation, high-temperature resistance, and mechanical strength, making it an ideal choice for electronic, electrical, and other high-demand environments.

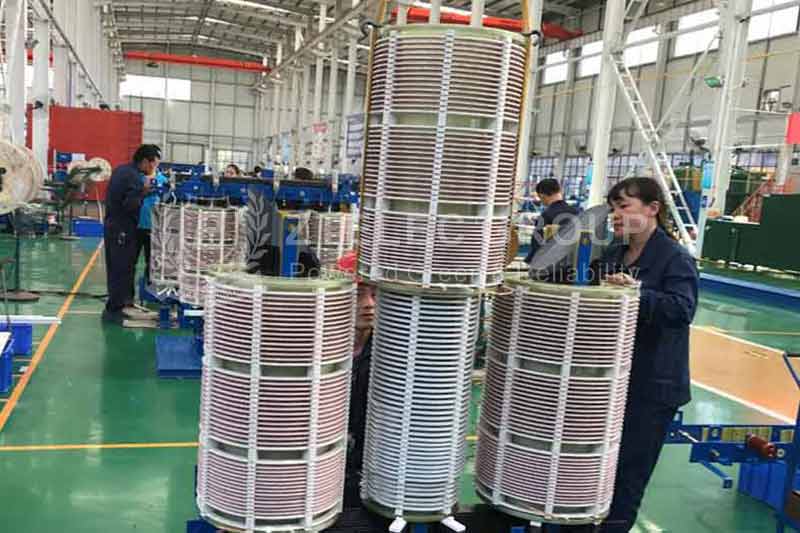

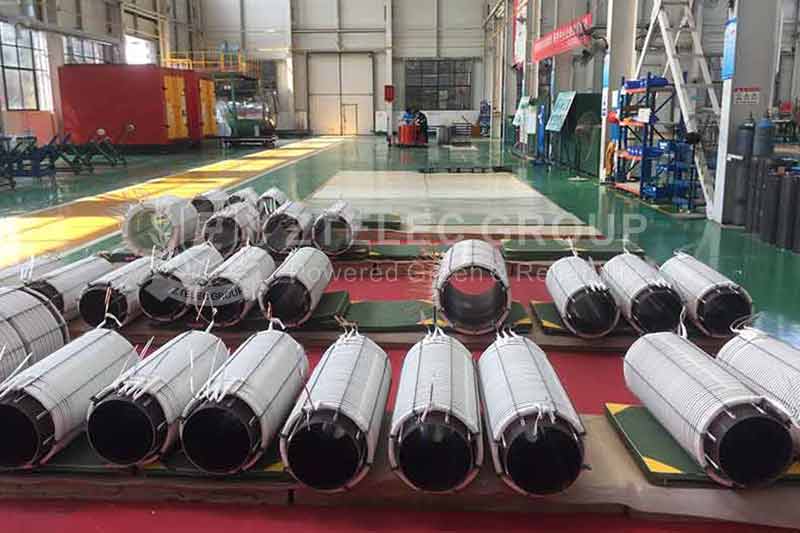

3240 Epoxy Glass Fiber Laminated Sheet

1.What is the 3240 Epoxy Board?

The 3240 epoxy board is a high-performance insulating material made from epoxy resin and fiberglass composite. It possesses excellent electrical insulation, high-temperature resistance, chemical corrosion resistance, and mechanical strength, commonly used in electrical, electronic, and industrial equipment. Its main characteristics include high thermal stability, making it suitable for use in harsh environments, widely applied in circuit boards, insulation components, and aerospace fields.

3240 Epoxy sheet

2.Performance Characteristics of 3240 Epoxy Board

Key features of the 3240 epoxy board include:

· Electrical Insulation: Ensures safe use in high-voltage environments.

· Chemical Corrosion Resistance: Capable of resisting various chemical substances.

· Mechanical Strength: Maintains stability under high-load conditions.

· Thermal Stability: Effectively operates in high-temperature environments, extending product lifespan.

3240 epoxy board

3.Industry Applications of 3240 Epoxy Board

In terms of electrical performance, the 3240 epoxy board exhibits extremely low dielectric loss and excellent dielectric strength, making it outstanding in high-frequency and high-voltage electrical environments. For example, in high-tech fields such as radar systems and satellite communication equipment, the 3240 epoxy board ensures stable signal transmission and reliable equipment operation.

Regarding heat resistance, the 3240 epoxy board can withstand a continuous working temperature of up to 150°C and can endure even higher temperatures for short periods. This property makes it perform excellently in high-temperature environments, such as around automobile engines and in industrial kiln linings. For instance, using 3240 epoxy board in the spark plug insulator of an automobile engine can effectively resist high temperatures and pressures, ensuring normal engine ignition.

In terms of mechanical performance, the 3240 epoxy board boasts high tensile, flexural, and impact strengths, allowing it to provide reliable support and protection in applications requiring substantial mechanical stress, such as crane structural components and construction machinery parts.

Additionally, the 3240 epoxy board demonstrates excellent moisture resistance and corrosion resistance. In humid environments, such as underground pipelines and marine engineering facilities, it effectively resists moisture and chemical substance erosion, extending equipment lifespan.

In the medical industry, the 3240 epoxy board is widely used for the shells and internal insulating components of medical devices due to its good biocompatibility and insulation properties. In the renewable energy sector, it also plays a crucial role in the encapsulation of solar panels and the manufacturing of wind turbine blades.

As technology continues to advance, the applications of the 3240 epoxy board will further expand. The demand for environmentally friendly materials will promote improvements in production processes, potentially leading to more sustainable and enhanced products. Furthermore, as electronic devices become smaller and more high-performing, the 3240 epoxy board will play an increasingly important role in emerging technologies, driving industry innovation and development.

In summary, the 3240 epoxy board, with its superior performance and wide-ranging applications, is poised to continue playing a vital role in the market in the future.

- more+releated article

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-12Price of a 1600kVA 10kV Cast Resin Dry-Type Tr

- 2025-12-12How to Choose Epoxy Laminate Materials for Gen

- 2025-12-11Protection Configuration Principles for 35kV D

- 2025-12-11The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-10Application Prospects of 10kV/35kV Oil-Immerse

- 2025-12-09How to Reduce the Maintenance Cost of Oil-Imme

- 2025-12-09How to Choose the Best 110 kV Oil-Immersed Pow

- 2025-12-08Heat-Resistant DDP Insulation Paper