What is Bakelite and Phenolic Board and what is the difference between the two insulating materials

2024-06-27 15:11 | By: ZTELEC-www.ztelecgroup.com | 80click

What is Bakelite

Bakelite, formally known as polyoxybenzylmethylenglycolanhydride, is a thermosetting phenol formaldehyde resin. It was the first plastic made from synthetic components.

characteristics of Bakelite:

Thermosetting: Once set, it cannot be melted for reshaping, which gives it a permanent form.

Electrical Nonconductivity: It has excellent insulating properties, making it ideal for electrical and electronic components.

Heat Resistance: Bakelite can withstand high temperatures without losing its structural integrity.

Chemical Resistance: It is resistant to various chemicals, adding to its durability.

Versatility: It can be molded into different shapes and forms, which led to its widespread use in a variety of products, from kitchenware to jewelry and electrical insulators.

Bakelite’s development marked a significant milestone in the chemical industry and paved the way for the modern plastics industry. It remains an important material in applications where its unique properties are required.

What is phenolic board

Phenolic board, also known as phenolic panel or high-pressure laminate (HPL) panel, is a highly resistant architectural panel. It’s made of natural core material layers and thermosetting resins, manufactured under high pressure and temperature.

phenolic boards points:

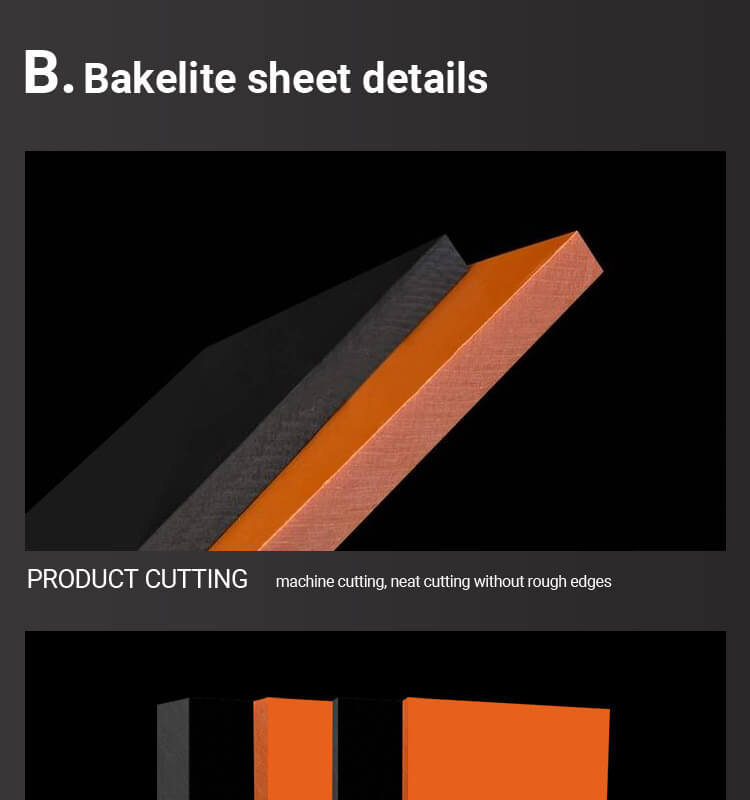

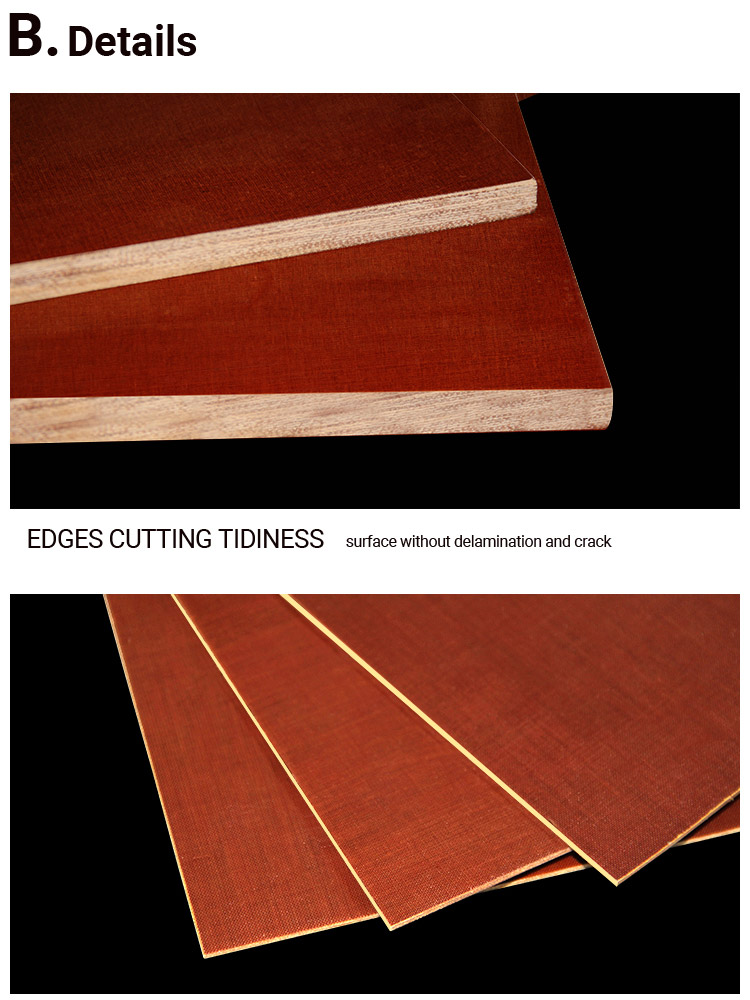

Composition: Phenolic boards are composed of layers of paper or fabric impregnated with phenolic resin. The layers are bonded together under high pressure and heat to create a solid, uniform material.

Durability: They are known for their strength, durability, and resistance to moisture, making them suitable for use in damp environments like bathrooms, toilets, and locker rooms.

Versatility: These boards can be used for a variety of applications, including furniture, cabinetry, and as a substrate for countertops and other surfaces.

Machinability: Phenolic boards can be easily machined and fabricated into different shapes, which allows for design flexibility in construction and manufacturing processes.

Resistance: They offer excellent resistance to chemicals, impact, and heat, which makes them ideal for use in laboratories, transportation, and defense industries.

Phenolic boards are a popular choice in construction and other industries due to these properties, providing a sustainable and high-quality option for architects and designers.

What is the difference between Bakelite and Phenolic board uses?

Bakelite and phenolic boards are both made from phenolic resins, but they are used in different applications due to their distinct properties:

Bakelite:

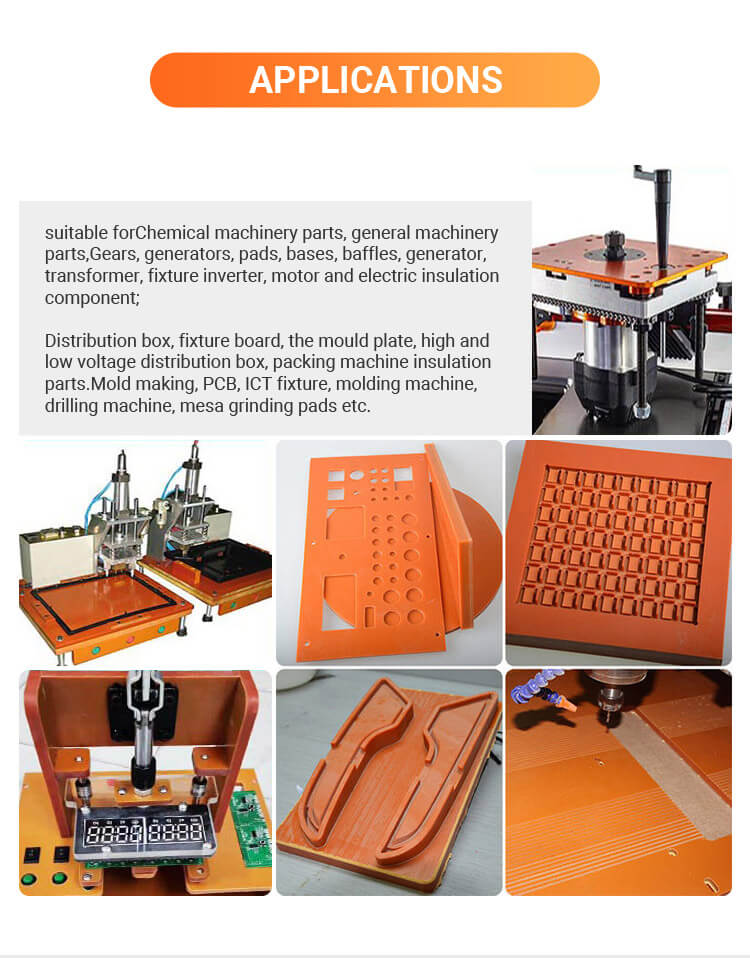

Electrical Components: Due to its nonconductivity and heat-resistant properties, Bakelite is often used in electrical insulators, radio and telephone casings.

Consumer Goods: It’s found in kitchenware, jewelry, pipe stems, children’s toys, and firearms because of its ability to be molded into various shapes.

Collectibles: The retro appeal of old Bakelite products has made them collectible items.

Phenolic Board:

Construction: Phenolic boards are used in architectural panels, particularly in damp environments like bathrooms and locker rooms due to their moisture resistance.

Furniture: They are utilized for furniture, cabinetry, and as substrates for countertops because of their durability and resistance to chemicals and impact.

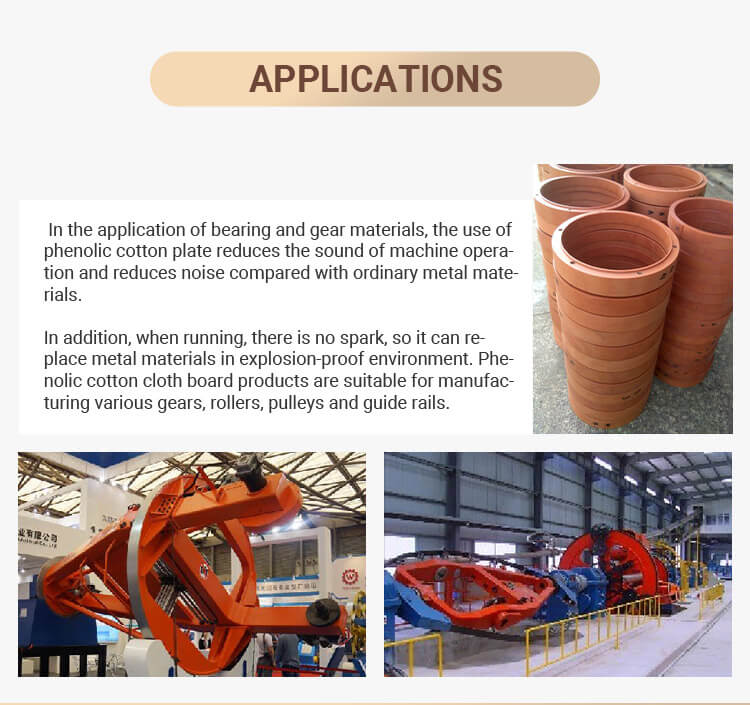

Industrial Applications: In industries like laboratories, transportation, and defense, phenolic boards are chosen for their heat and chemical resistance.

The main difference lies in their typical uses, with Bakelite being more common in electrical and consumer products, while phenolic boards are widely used in construction and industrial applications. Both materials share the benefits of phenolic resins, such as durability and resistance to heat and chemicals, but their specific uses are tailored to their unique properties and the requirements of the applications they serve.

What is the difference between the manufacture of bakelite and phenolic panels?

The manufacturing processes of Bakelite and phenolic panels differ primarily in the materials used and the methods of curing the resin:

Bakelite Manufacturing:

Initial Reaction: The process begins with the heating of phenol and formaldehyde in the presence of a catalyst such as hydrochloric acid, zinc chloride, or ammonia.

Condensation Product: This creates a liquid condensation product, known as Bakelite A, which is soluble in alcohol, acetone, or additional phenol.

Further Heating: Upon further heating, it transforms into a solid B stage (resitol) that can still be softened by heat to a final shape in a mold.

Final Curing: Both A and B stages can be brought to a completely cured thermoset C stage (Bakelite C, or true Bakelite) by being heated under pressure.

Phenolic Panel Manufacturing:

Layering: Phenolic panels are made by layering paper or fabric impregnated with phenolic resin.

High Pressure and Temperature: These layers are then bonded together under high pressure and temperature to create a solid, uniform material.

Eco-Friendly: The process is designed to be eco-friendly, often avoiding the use of chlorine, fluorine, bromine, and other organic halogen compounds.

Modular Production: Less material is wasted in their production, and they can be manufactured and used in modular configurations, making them cost-effective.

In summary, Bakelite is produced through a chemical reaction and curing process that results in a thermosetting plastic, while phenolic panels are created by layering and curing materials under high pressure and temperature to form a dense and durable laminate.

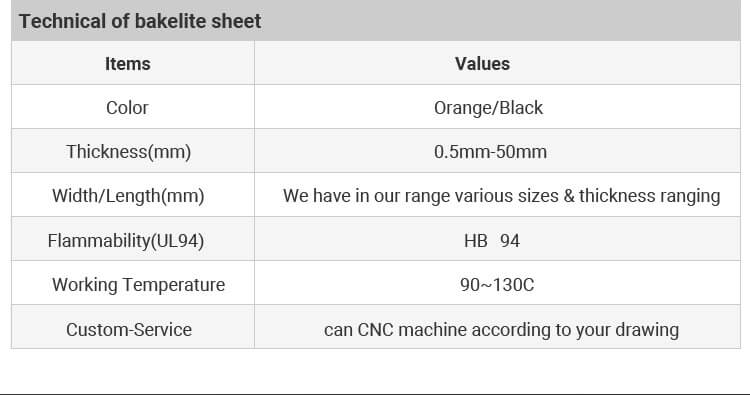

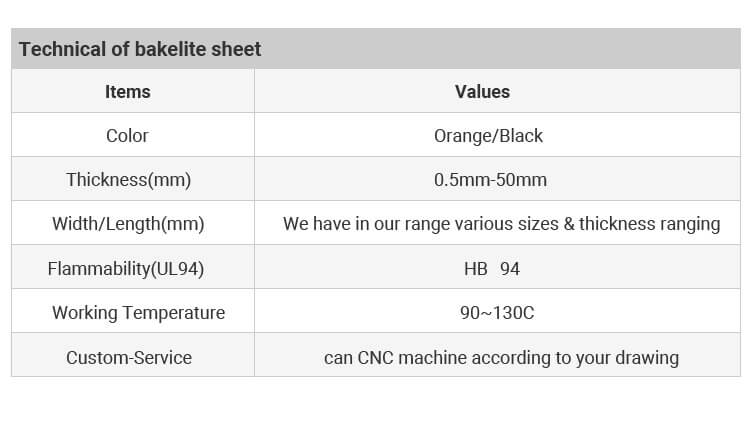

What is the difference between Bakelite and Phenolic Board Data

What is the difference in price between Bakelite and Phenolic panels?

The price difference between Bakelite and Phenolic panels can vary based on factors such as the thickness of the material, the specific type of panel, and the supplier. Generally, Bakelite is considered to be a more economical option when mechanical and insulating properties are required. It’s mentioned that the price of raw materials for Bakelite is nearly 50% of the price of ABS and also lower than the price of epoxy glass fiber board. Phenolic panels, on the other hand, are crafted for durability and design freedom, which might reflect in their pricing.

For the most accurate and current Electrical insulation pricing, it would be best to contact suppliers directly or request quotes based on your specific needs. If you need assistance with finding suppliers or getting quotes, I’m here to help!

tags:insulation failure transformertransformer short circuittransformer overheatingtransformer overloadtransformer maintenance

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri