Differences between FR4 and FR5 fiberglass laminates

FR4 and FR5 are both types of fiberglass-reinforced epoxy laminate materials used in the construction of printed circuit boards (PCBs), but they have some key differences:

Composition:

FR4: Made of woven fiberglass cloth impregnated with an epoxy resin, with a Tg (glass transition temperature) rating indicated by the “4” in FR4.

FR5: Similar to FR4 in composition but typically has a higher Tg rating1.

Glass Transition Temperature (Tg):

FR4: Generally has a Tg rating around 130-140°C, which is the temperature at which the material transitions from a rigid to a more flexible state.

FR5: Has a higher Tg rating, often around 150-170°C or even higher, making it suitable for applications requiring higher-temperature operation or processing.

Temperature Resistance:

FR4: Suitable for standard electronic applications with moderate

operating temperatures.

FR5: Chosen for applications where higher temperature resistance is necessary, such as high-frequency and high-speed communication devices, military applications, and other specialized electronics.

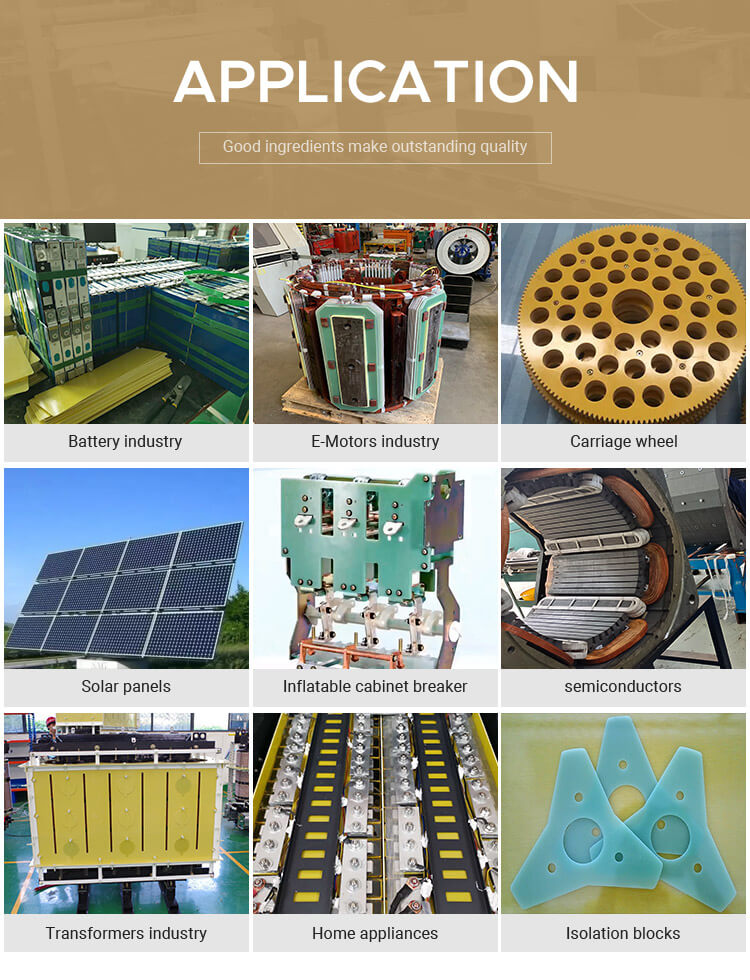

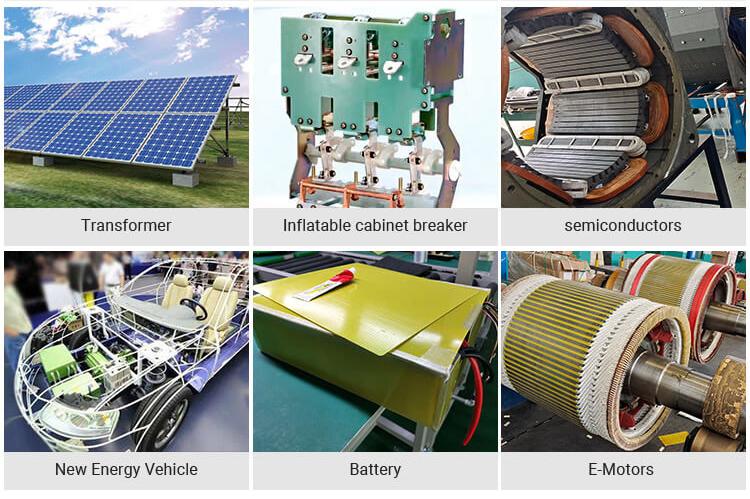

Applications:

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri