glass-reinforced epoxy laminates G10 vs G11 comparison

2024-06-22 09:47 | By: ZTELEC-www.ztelecgroup.com | 98click

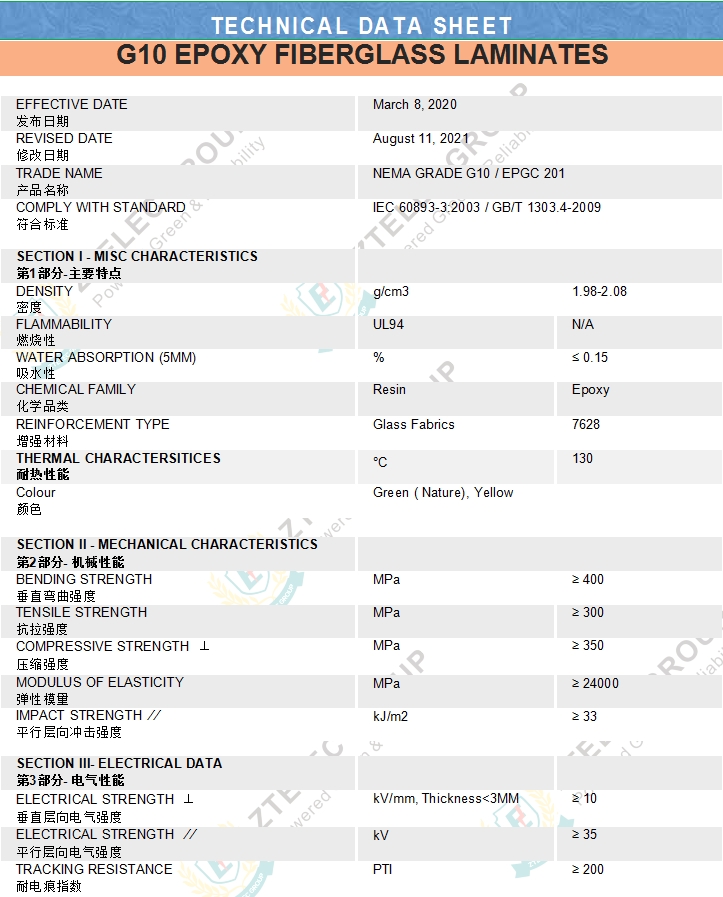

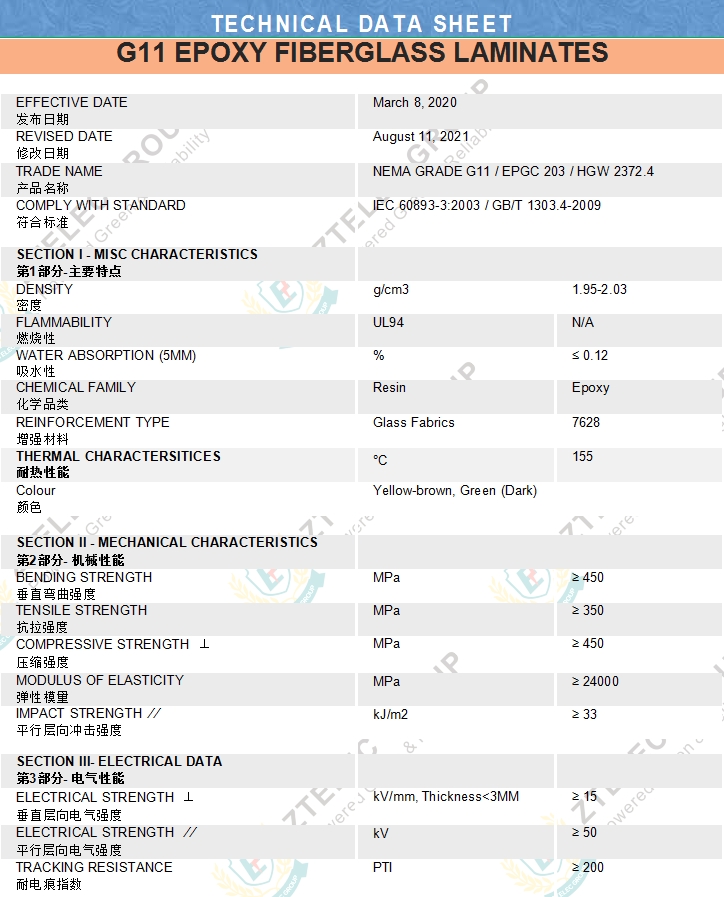

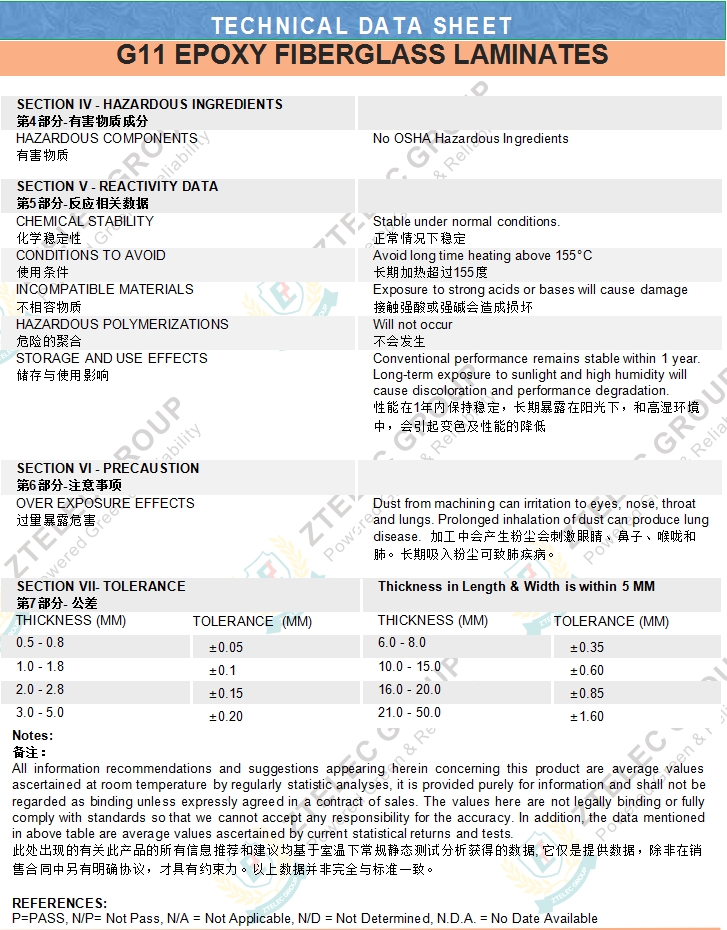

G10 and G11 are both types of glass-reinforced epoxy laminates, commonly used in electrical and mechanical applications.

Here’s a comparison of their properties:

Heat Resistance: G10 has good heat resistance, but G11 is superior, making it more suitable for high-temperature applications.

Electrical Insulation: Both offer excellent insulation, but G11 performs better at high temperatures due to its higher epoxy content.

Mechanical Strength: G11 retains its strength better at elevated temperatures compared to G10.

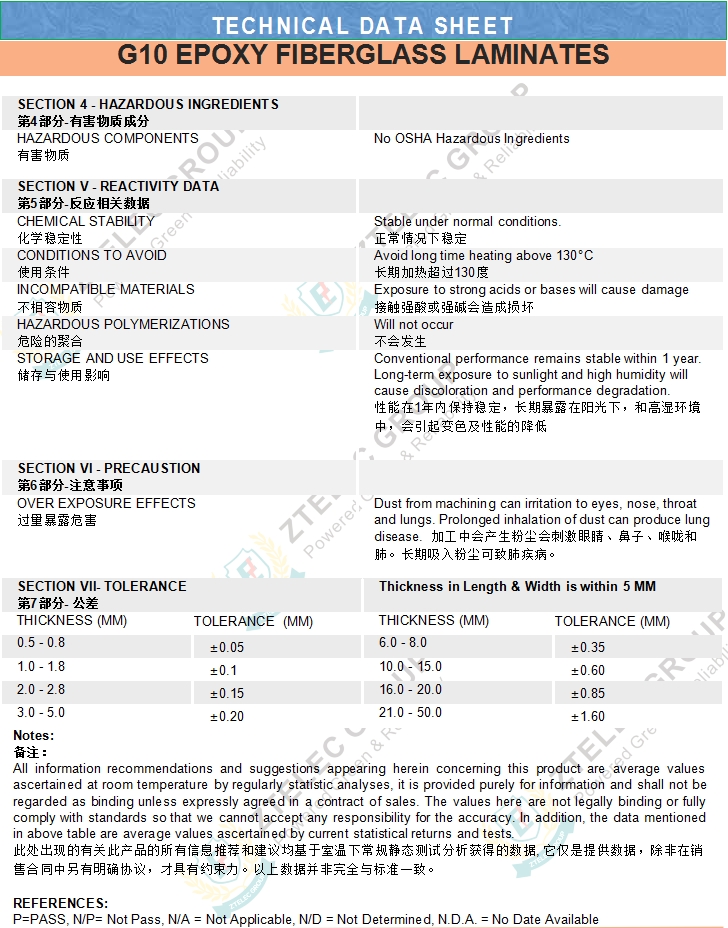

Moisture Absorption: Both materials have low moisture absorption.

Chemical Resistance: They both provide good chemical resistance.

Cost: G11 generally costs more due to its enhanced heat resistance.

Applications:

G10: Used in printed circuit boards (PCBs), insulators, and knife handles due to its durability and resistance to corrosion.

G11: Ideal for high-temperature electrical applications, aerospace components, and insulating washers and spacers that operate under extreme conditions.

The choice between G10 and G11 will depend on the specific requirements of your application, especially concerning thermal performance and budget considerations. G10 is an excellent choice for general electrical and mechanical applications, while G11 is better suited for environments with higher temperatures.

G-10 is stronger, but G-11 is better insulated and can withstand higher temperatures.

G10date vs G11 date

G10date

G11 date

tags:insulation failure transformertransformer short circuittransformer overheatingtransformer overloadtransformer maintenance

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri