product description

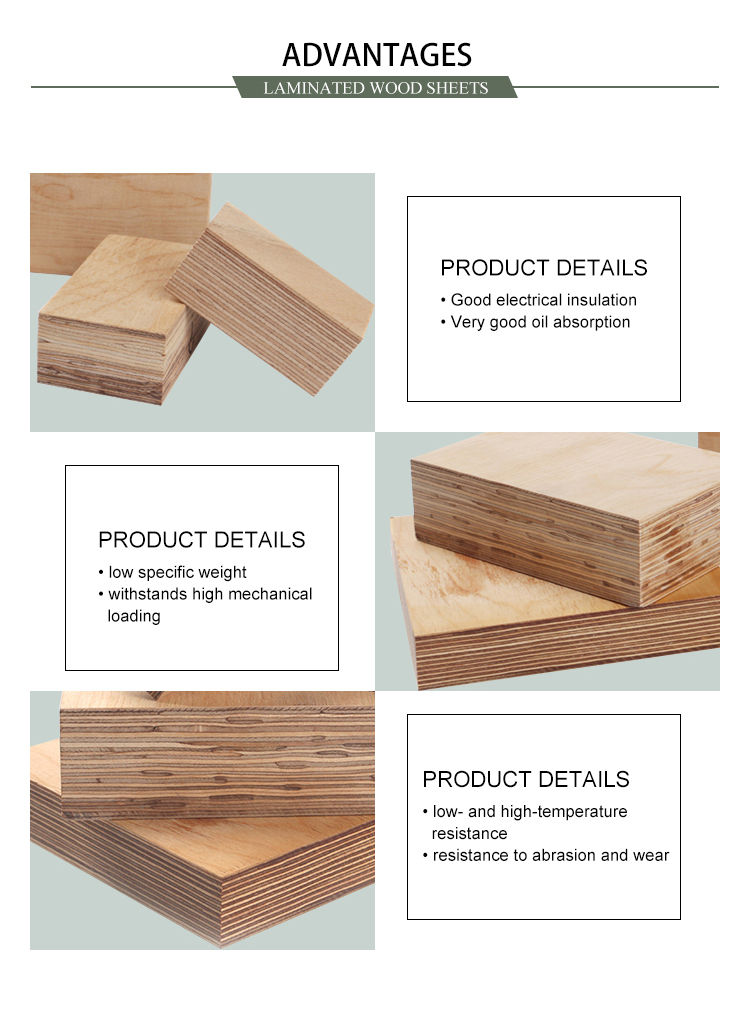

what is laminated sheet

A laminated sheet is a type of composite material composed of multiple layers that are bonded together under heat and pressure1. It’s an artificial material that is often used to cover wooden furniture to give them attractive looks. The process involves pressing thin layers of paper and resins together.

There are several benefits of using laminate sheets, such as waterproofing. They are hard to touch and provide a durable and decorative surface for various applications.

Laminate sheets can be used in a variety of ways, including in the manufacturing of 3D objects. This is done by stacking and laminating thin sheets of material, with the lamination method being bonding, ultrasonic welding, or brazing. The final shape is achieved by laser cutting or CNC machining.

There are different types of laminate sheets based on the build material used (such as paper, plastic, metal, or woven fibre composites), the forming methods employed (like CNC milling, laser cutting, or aqua blasting), and the lamination technique used to bond the sheets together (such as adhesive bonding, thermal bonding, and ultrasonic welding).

In some cases, the sheets are formed and then bonded, like in the Computer-Aided Manufacturing of Laminated Engineering Materials (CAM-LEM) process. In other cases, they are bonded and then formed, like in the Ultrasonic Additive Manufacturing (UAM) process

key properties:

Sure, here are the key properties of laminated sheets:

Strength and Stiffness: Laminates are known for their exceptional strength and stiffness. They can withstand significant pressure without deforming or breaking, making them ideal for load-bearing applications.

Impact Resistance: Laminates exhibit impressive impact resistance, making them highly durable in areas with heavy foot traffic or potential for impact, such as flooring and countertops.

Flexibility: While laminates are strong and rigid, they also possess a degree of flexibility, which prevents them from cracking under minor stress or movement.

Thermal Properties: Laminates have relatively low thermal conductivity, meaning they do not conduct heat efficiently. This property makes them ideal for use in environments with varying temperatures. They are also less prone to expanding or contracting under extreme temperature changes due to their low thermal expansion coefficient.

Fire Resistance: Laminates with fire-resistant properties are available, making them suitable for applications where fire safety is a concern.

Chemical Resistance: Laminates are highly resistant to various chemicals, including acids and solvents, ensuring they can withstand exposure in challenging environments.

Stain and Moisture Resistance: The protective overlay on laminates provides excellent stain resistance, making them easy to clean and maintain. They are inherently moisture-resistant, making them suitable for use in areas prone to high humidity, such as kitchens and bathrooms.

Aesthetic Properties: Laminates come in an extensive array of designs, patterns, and textures, allowing for versatile and creative applications in interior design. They maintain color stability even when exposed to sunlight or artificial light, ensuring they retain their original appearance over time.

Antibacterial Features: Some laminates have antibacterial features, making them suitable for use in hospitals and heavy industries.

Heat Resistance: Certain laminates are heat resistant.

These properties make laminated sheets a versatile material for a wide range of applications, from furniture to construction

Laminate Benefits

Laminated sheets offer a multitude of benefits, making them a popular choice for various applications. Here are some key benefits:

High Durability: Laminate sheets are extremely durable and work as a protective layer on the furniture’s surface. They can withstand stains, spills, scratches, smudges, and other damages.

Moisture Resistant: Laminates are waterproof and moisture-resistant, making them suitable for areas prone to high humidity, such as kitchens and bathrooms.

Antifungal Properties: Some laminates have antifungal features, making them suitable for use in hospitals and heavy industries.

Maintenance Friendly: Laminate sheets are easy to clean and maintain, making them a practical choice for many applications.

Affordability: Laminates are a cost-effective solution for enhancing the aesthetics and functionality of various surfaces.

Wide Range Availability: Laminates come in an extensive array of designs, patterns, and textures, allowing for versatile and creative applications in interior design.

Natural Appeal: Laminates offer an extensive range of finishes that mimic the natural beauty of materials like wood grains, stones, and other textures.

Low Maintenance: Laminates require minimal maintenance, making them a convenient choice for many applications.

Pre-finished Product: Laminates come as pre-finished products, saving time and effort during installation.

These benefits make laminated sheets a versatile material for a wide range of applications, from furniture to construction

Laminate Benefits

Laminated sheets offer a multitude of benefits, making them a popular choice for various applications. Here are some key benefits:

High Durability: Laminate sheets are extremely durable and work as a protective layer on the furniture’s surface. They can withstand stains, spills, scratches, smudges, and other damages.

Moisture Resistant: Laminates are waterproof and moisture-resistant, making them suitable for areas prone to high humidity, such as kitchens and bathrooms.

Antifungal Properties: Some laminates have antifungal features, making them suitable for use in hospitals and heavy industries.

Maintenance Friendly: Laminate sheets are easy to clean and maintain, making them a practical choice for many applications.

Affordability: Laminates are a cost-effective solution for enhancing the aesthetics and functionality of various surfaces.

Wide Range Availability: Laminates come in an extensive array of designs, patterns, and textures, allowing for versatile and creative applications in interior design.

Natural Appeal: Laminates offer an extensive range of finishes that mimic the natural beauty of materials like wood grains, stones, and other textures.

Low Maintenance: Laminates require minimal maintenance, making them a convenient choice for many applications.

Pre-finished Product: Laminates come as pre-finished products, saving time and effort during installation.

These benefits make laminated sheets a versatile material for a wide range of applications, from furniture to construction

laminated sheet use:

Laminated sheets have a wide range of applications due to their durability, versatility, and aesthetic appeal. Here are some of their common uses:

Furniture: Laminates are widely used to enhance the appearance of furniture and protect it from dust and moisture. They provide a smooth surface and an attractive look to the furniture at a low cost. They are mainly used on furniture countertops, floors, walls, ceilings, and many other applications.

Kitchen Countertops: Laminates are commonly used in kitchen countertops due to their durability, ease of cleaning, and wide range of design options.

Flooring: Laminates are a popular choice for flooring due to their durability, ease of maintenance, and variety of designs.

Wall Coverings: Laminates can be used to enhance the appeal of walls. They offer a great way to beautify spaces and also provide strength and protection to the elements of your property.

Commercial Spaces: In commercial and industrial settings, laminates are used for functional purposes. These laminates are thicker, stronger, and incredibly resistant. Many of the laminates used in the industry are designed to provide antibacterial properties and even fire retardation.

Decorative Elements: Decorative laminates are available in a wide variety of colors, textures, and designs, allowing property owners and designers to manifest their creative vision.

Remember, the specific use of a laminate sheet can depend on its type, such as high-pressure laminate, low-pressure laminate, and wood laminate

available in name grades:

Laminated sheets are available in various NEMA (National Electrical Manufacturers Association) grades. Each grade is designated by a specific combination of letters and numbers, which represent the type of reinforcement and resin used in the laminate. Here are some of the common NEMA grades for laminated sheets:

X, XP, XPC, XX, XXP, XXX: These grades are made of paper phenolic resin. They are used for mechanical and general purposes.

FR-1, FR-2, FR-3: These are fire retardant grades made of paper phenolic resin. They are used for mechanical and electrical applications.

L, LE: These grades are made of cotton phenolic resin. They are used for machinable and electrical applications.

C, CE: These grades are made of cotton phenolic resin. They are used for mechanical and general purposes.

FR-4, FR-5: These are fire retardant grades made of glass epoxy resin. They are used for mechanical applications.

G-3, G-5, G-9, G-7, G-10, G-11: These grades are made of woven glass with different types of resins (phenolic, melamine, silicone, epoxy). They are used for general purposes and electrical applications.

GPO-1, GPO-2, GPO-3: These grades are made of random weave glass with polyester resin. They are used for general purposes.

Each of these grades exhibits unique electrical, mechanical, and chemical performance characteristics and has specific uses based on these criteria. The choice of grade depends on the specific requirements of the application.

sheet sizes available:

Laminated sheets are available in a variety of sizes to meet different needs. Here are some of the standard sizes available:

8ft x 4ft (2440mm x 1220mm): This is the most widely used option due to its convenience, cost-effectiveness, and ease of use & transportation. It is ideal for most surfaces and projects.

9ft x 4.25 ft (2800mm x 1300mm): This size is used when the 8ft x 4ft size is just a bit short, such as for a kitchen countertop.

10ft x 4.25 ft (3050mm x 1300mm): This size is used for extensive projects and surfaces that need fewer seams.

Please note that these sizes can be customized to meet the needs of different customers. The choice of size depends on the specific requirements of the application

data sheets: