product description

G10 Description

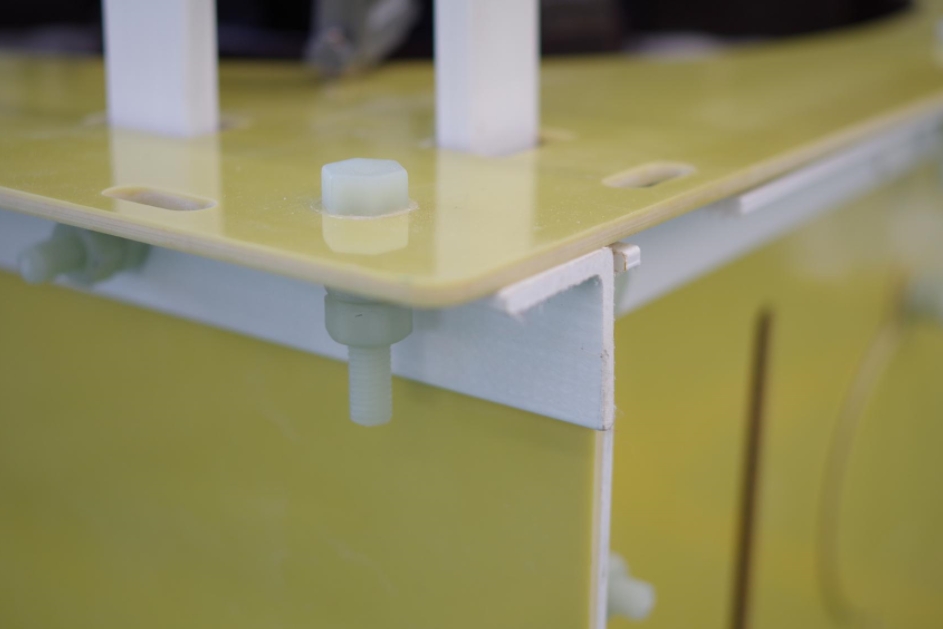

G10, also known as garolite, is a high-pressure fiberglass laminate and a type of composite material. It’s constructed by layering multiple sheets of glass cloth, which are then soaked in epoxy resin. The layers are compressed and heated until the epoxy cures, forming a rigid and durable material.

Here are some key properties and uses of G10:

High Strength: G10 is known for its robustness and is considered the toughest among glass fiber resin laminates.

Low Moisture Absorption: It maintains its properties even under humid or moist conditions.

Electrical Insulation: G10 has excellent electrical insulation properties, making it suitable for electronic applications.

Chemical Resistance: It resists a variety of chemicals, contributing to its versatility in different environments.

Heat Resistance: The material can withstand high temperatures without losing its structural integrity.

Applications: Initially used as a substrate for printed circuit boards, G10 is now also popular for making knife handles, grips for firearms, and other tools due to its strength and low density.

g10 colour

G10 material is available in a variety of colors. The natural color of G10 is a jade green, but it has been developed in up to 21 different colors in the FR4 variant. These colors include:

Red

Blue

Black

White

Orange

Glow-in-the-dark (Dayglow)

Tan

Ivory

Purple

Pink

Several shades of green

Greys

These color options allow for customization and aesthetic choices in applications where the appearance of the material is important, such as in knife handles or equipment casings.

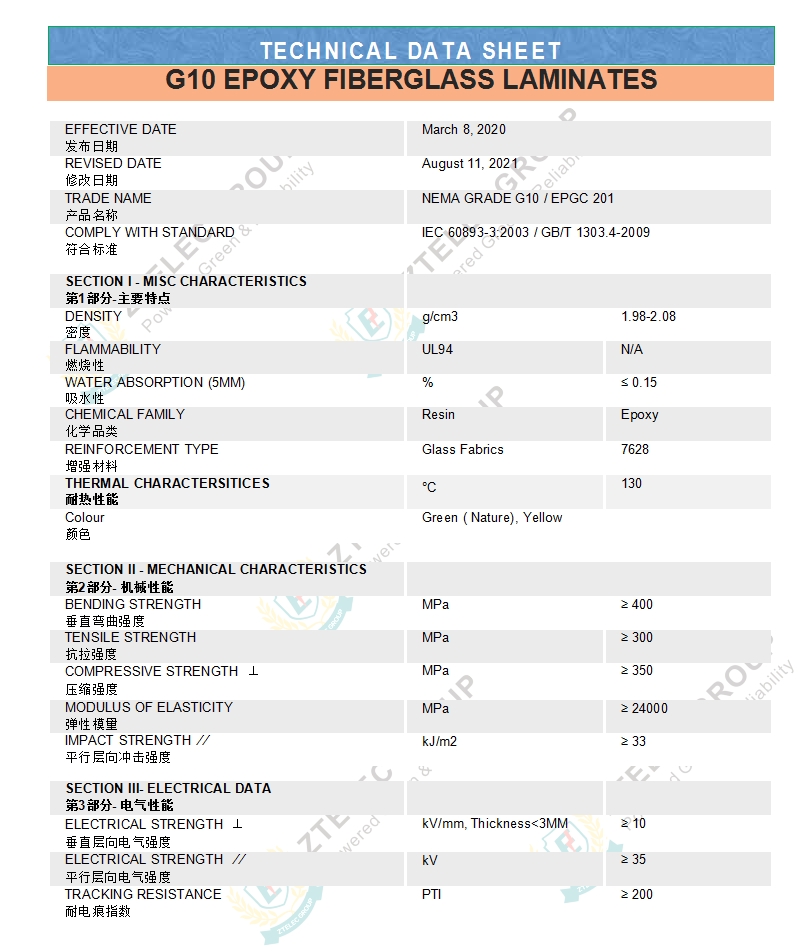

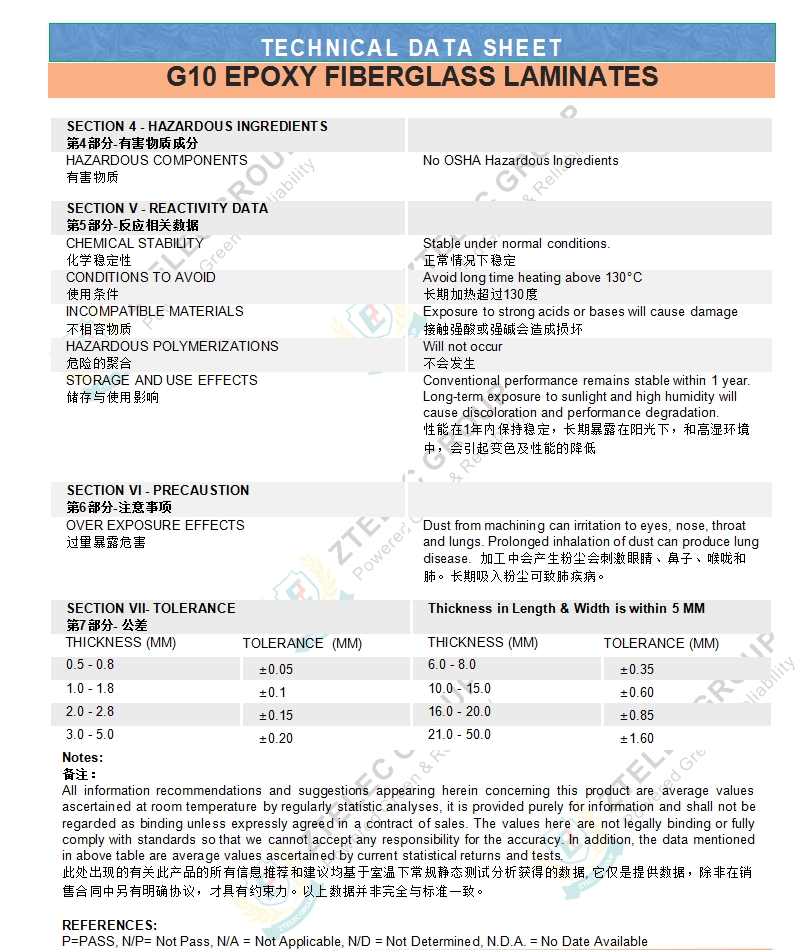

G10 technical parameters and performance characteristics

G10 is a high-performance composite material known for its excellent mechanical and electrical properties. Here are some of the technical parameters and performance characteristics of G10:

Composition: It’s made of an epoxy resin binder and glass epoxy composite, which contribute to its strength and durability.

Chemical Resistance: G10 offers impressive resistance to chemicals, making it suitable for various industrial applications.

Electrical Properties: The material has outstanding electrical insulation capabilities, compliant with MIL-I-24768/2 military specification for insulation plastic laminated thermosetting materials.

Mechanical Strength: G10 is strong and rigid, providing high strength and stability for structural components.

Thermal Properties: It can withstand high temperatures and is suitable for cryogenic applications, maintaining mechanical properties with minimal thermal expansion and mass loss.

Flame Retardant: While G10 itself is not flame retardant, its variant FR-4 includes additional fire safety features.

These characteristics make G10 an ideal choice for a wide range of applications, including electrical insulators, mechanical parts, and components that require high strength and stability under various environmental conditions. Always ensure to consult with the material specifications for your specific application to ensure proper performance and safety.

HOW IS G10 MADE?

G10 is manufactured through a process that involves several key steps to create its strong and durable structure. Here’s an overview of how G10 is made:

Composition: The foundation of G10 material is a combination of glass fabric and epoxy resin blend.

Layering: Multiple layers of glass cloth are soaked in epoxy resin.

Compression and Curing: The soaked layers are then compressed under high pressure and heat. This step is crucial as it allows the epoxy to cure and harden, forming a solid laminate.

Machining: Once cured, the G10 material can be precision machined into various shapes and sizes to meet specific requirements.

Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure consistency and performance of the final product.

The result is a high-pressure fiberglass laminate that is known for its high strength, low moisture absorption, and excellent electrical insulation and chemical resistance. These properties make G10 suitable for a wide range of applications, including electrical components and knife handles. It’s important to handle G10 safely, especially during cutting or grinding, to avoid inhaling any potentially harmful dust.

CAN G10 BE USED IN HIGH TEMPERATURE ENVIRONMENTS?

Yes, G10 can be used in high-temperature environments, but there are limits to its heat resistance. G10 exhibits remarkable heat resistance with a temperature rating of up to 180 degrees Celsius. This makes it suitable for various applications where heat resistance is required.

However, it’s important to note that the epoxy resin in G10 can be affected by temperatures above 140 degrees Celsius. For applications requiring resistance to higher temperatures, materials like G11 or G7, which can withstand higher temperatures, should be considered.

What are the advantages and disadvantages of G10?

G10 material is well-regarded for its numerous advantages, especially in applications requiring durability and resistance to various environmental factors. Here are some of the key advantages and disadvantages of G10:

Advantages:

Durability: G10 is highly resistant to impact, abrasion, and moisture, making it ideal for outdoor and tactical applications.

Water Resistance: It does not warp or rot over time, which is beneficial for items frequently exposed to moisture.

Low Maintenance: G10 requires minimal upkeep and can be cleaned easily with soap and water.

Chemical Resistance: It stands up well against chemicals and solvents, suitable for harsh environments.

Strength-to-Weight Ratio: G10 is strong yet lightweight, which is advantageous for manufacturing and handling.

Non-Conductive: It is an excellent insulator, making it a good choice for electrical applications.

Disadvantages:

Grip: When wet, G10 can become slippery, which might be a concern for handles or grips.

Aesthetic: Some users find G10 to feel plasticky, which may not be as appealing as natural materials like wood or bone.

Cost: Compared to mass-produced alternatives, G10 handle scales can be more expensive.

Brittleness: Under severe impacts, G10 may crack or chip, despite its overall durability.

These properties make G10 a versatile material for various applications, from knife handles to electronic insulators. However, the choice of material should always be based on the specific requirements and constraints of the intended application.

What are the uses of G10

G10 material is highly valued for its strength, durability, and excellent electrical insulation properties. Here are some of the primary uses of G10:

Electrical Components: Due to its excellent electrical insulation, G10 is commonly used in the manufacturing of circuit boards and high-voltage insulators.

Knife Handles: The material’s strength and resistance to moisture make it ideal for knife handles, providing a durable and stable grip2.

Firearms Manufacturing: G10 is also used to produce grips for firearms, as it offers an excellent grip surface and is highly resistant to impact.

Cryogenic Applications: Its ability to withstand high heat and cryogenic conditions makes G10 suitable for use in environments with extreme temperatures.

Marine Applications: The material’s resistance to water and chemicals allows it to perform well in marine settings.

Sports Equipment: High-end sporting equipment often utilizes G10 for its balance of strength and lightweight properties.

Aerospace Components: The aerospace industry values G10 for its consistent dimensional stability over a range of temperatures.

What is the price of G10?

The price of G10 material can vary depending on the size, thickness, and quantity you’re looking to purchase. For example, a basic cut-to-size sheet of G10/FR-4 can start at around $25.00 for a minimum line item. However, for custom sizes or larger quantities, the price may differ.

It’s also important to note that prices can fluctuate based on the supplier, location, and current market conditions. For the most accurate and up-to-date pricing, it’s best to request a quote directly from manufacturers or suppliers of G10 material.

If you’re considering purchasing G10 for your projects, keep in mind that investing in higher quantities can often reduce the unit cost, and some suppliers may offer discounts for bulk orders12. Always ensure to check with the supplier for any additional costs such as shipping, handling, or taxes that might apply to your order.

Where to find G10

You can find G10 material at various suppliers that specialize in composite materials. Here are a few options where you can purchase G10:

Maker Material Supply: They offer a wide range of G10 sheets in different colors and sizes, suitable for knife handle liners and other applications.

Professional Plastics: This supplier provides G10/FR-4 sheets that can be ordered online, with options for cut-to-size sheets and full sheets2.

Artisan Supplies: They cater to knifemaking supplies, including G10 sheets in various thicknesses and dimensions.

These suppliers typically have online stores where you can view their inventory and place orders. Prices may vary based on the size and quantity of the material, so it’s a good idea to compare options and request quotes where possible. Remember to consider shipping costs and availability when selecting a supplier, especially if you require the material for a time-sensitive project.