product description

G-11 is a high-temperature glass epoxy laminate, which is a glass fiber reinforced epoxy resin composite material. Same characteristics as G-10, able to withstand very high temperatures

ztelecgroup manufactures G-11 and several other glass epoxy laminates. Learn more about the benefits, uses, and features of G-11.

1.What is G-11?

G-11 is a thermoset industrial fiberglass laminate made from filament glass cloth and epoxy resin. Its natural color ranges from yellow-green to amber. G-11 provides excellent mechanical and dielectric strength under a variety of conditions. Its insulation performance and temperature resistance are both greater than G-10.

There are two types of G-11 glass epoxy resin available. Class H is suitable for applications with operating temperatures up to 180 degrees Celsius. Class F is designed for applications with temperatures up to 150 degrees Celsius.

G-11 is related to FR-5 glass epoxy and is the flame retardant version.

Notable G-11 features* include:

Tensile Strength: 63,000 psi

Compressive Strength: 37,000 psi

Flexural Strength – LW-A 0.125″: 75,000 psi

Bond strength: 2,200 psi 15 MPa

Shear strength: 22,000 psi 151 MPa

Hardness, M rating: 112

Specific gravity: 1.82

Flammability rating: 94HB

Maximum temperature: 180°C (356°F)

Water absorption rate - 24 hours: 0.20

49°C Izod Impact Strength – LW: 12.00

ztelecgroup provides this data for informational purposes only and does not imply any warranty as to its use or application. Test results for specific panels or batches are available upon request and for a fee.

2.G-11 vs G-10 comparison

G-11 and G-10 are both glass epoxies. They share some common properties and some significant differences. G-11 has a higher operating temperature than G-10 glass epoxy. G-11 also has better mechanical properties at higher temperatures than G-10. It is generally considered to be a better insulator than G-10.

G-11 Manufacturing

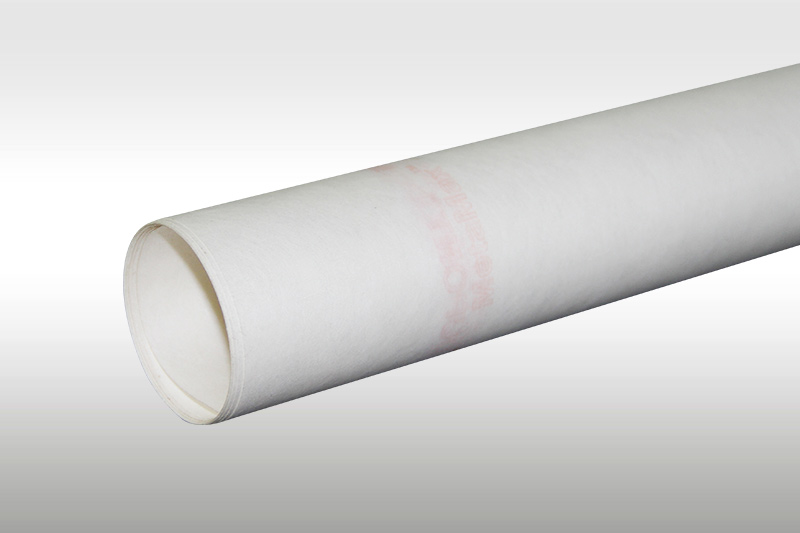

The G-11 can be machined using standard cutting tools. It can also be wound into a tube using convolution or filament winding methods.

G-11 Benefits

G-11 has several benefits. It is suitable for use in wet and dry conditions and can withstand temperatures up to 180 degrees Celsius (depending on grade).

3.Notable advantages of the G-11 include:

characteristic:

Material composition: G-11 is mainly composed of glass fiber and epoxy resin, which is cured at high temperature.

Temperature tolerance: G-11 has good high temperature stability and can operate at relatively high temperatures without losing performance.

Electrical properties: As an insulating material, G-11 has excellent electrical insulation properties and is suitable for use in the field of electrical engineering.

Mechanical Strength: Has high mechanical strength and rigidity, making it suitable for applications that need to withstand certain mechanical loads.

Chemical stability: It has good resistance to many chemicals and shows high chemical stability.

G-11 material application

ztelecgroup offers G-11 in tablet, rod and tube forms. We can cut the material to size based on your project needs. Here are some common applications for G-11:

application:

Electrical Engineering: G-11 is widely used in the manufacture of electrical insulation parts, such as insulators, electrical insulation panels, etc.

Mechanical Engineering: Due to its high temperature stability and mechanical strength, G-11 can be used to manufacture mechanical parts, gears, support structures, etc.

Application in high temperature environment: Suitable for occasions where performance needs to be maintained in high temperature environment, such as insulation of high temperature equipment.

Chemical industry: In some environments that need to resist chemical corrosion, G-11 can be used as a component material of chemical equipment.

Aerospace: Due to its light weight, high strength and high temperature stability, G-11 also finds applications in the aerospace sector, such as aircraft components.

4.g11 Technical Parameters

5.Where to Buy G-11 High Temperature Glass Epoxy Laminate

There are manufacturers in China that specialize in manufacturing various insulation materials. We have listed one of the high-quality manufacturers. Interested friends can inquire.