Comparison and selection of FR4 material and FR5 material

What is FR4 ?

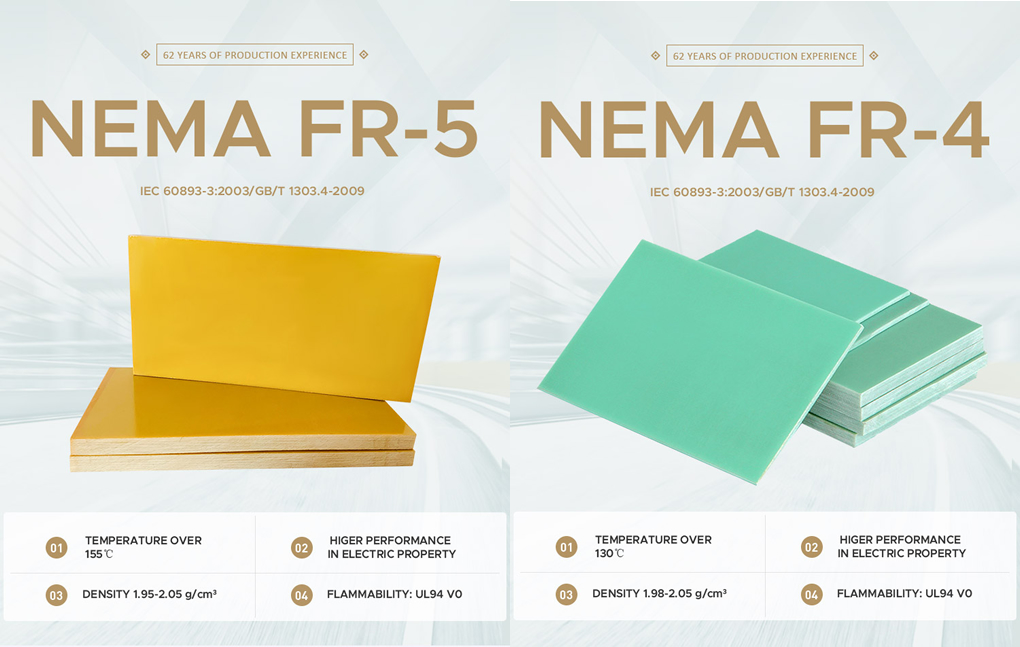

FR4 material is a common composite material that is widely used in the manufacture of electronic circuit boards. It consists of fiber glass cloth and imported epoxy resin, and has high mechanical properties, dielectric properties, electrical insulation properties. The insulation class is F, and the main colors are white (primary), light green, black and yellow.

What is FR5?

FR5 (Flame Retardant Level 5) is a common fiber glass reinforced epoxy resin insulation material. It is made of epoxy resin and fiber glass cloth. FR5 has excellent chemical resistance, high tensile strength, low moisture absorption and high impact strength.

And it is mainly used in circuit board manufacturing in the electronic and electrical industry.

The difference between FR4 and FR5

FR4 and FR5 are two common electronic substrate materials, which have obvious differences in performance and application.

1. FR4 is a fiber glass reinforced epoxy resin substrate material with good insulation properties and mechanical strength. In contrast, FR5 is a fiber glass reinforced polyimide substrate material with higher temperatures resistance and chemical corrosion resistance.

2. Due to the good thermal stability of FR5, it is suitable for electronic devices operating in high temperature environments, such as aerospace and military applications. FR4 is commonly used in general electronic devices, such as computer motherboards and mobile phone circuit boards.

3. Because FR5 materials are more expensive and production costs are higher, FR4 is preferred in some specific applications.

How to purchase FR4 and FR5?

FR4 and FR5, as commonly used electronic substrate materials, need to consider many aspects when purchasing.

First:you need to understand the physical properties and characteristics of FR4 and FR5 in order to make an informed choice based on your project needs. FR4 is a fiberglass laminate with high mechanical strength and heat resistance and suitable for conventional circuit board designs. FR5 is a higher performance material with better electrical properties and heat resistance and suitable for high frequency and high temperature environments.

Secondly:the quality and reliability of the material need to be considered. When purchasing, you should choose reputable suppliers and pay attention to the certification and quality standards of their products. When you communicate with suppliers, you can ask questions about material characteristics and applications to obtain more detailed information and recommendations.

Third:you need to consider the cost factor. FR4 is generally cheaper than FR5, but in some special applications, FR5's performance may be superior, so there is a trade-off between performance and cost. Decisions need to be made based on project requirements and budget.

Ztelec Group is a professional manufacturer of high-quality electrical insulation materials with more than 60 years of manufacturing experience.

If you need more product information and quotes, please contact us.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri