Three-phase oil-immersed transformers: the best choice for performance and application

What is a Three-Phase Oil-Immersed Transformer?

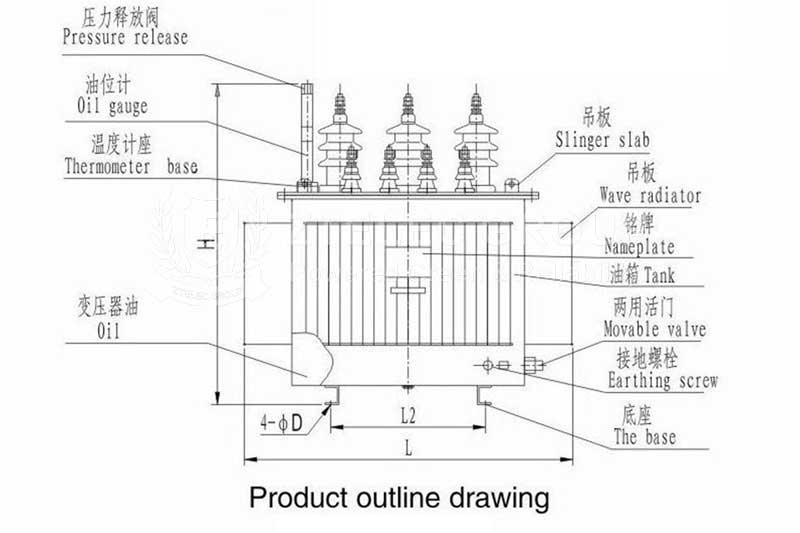

A three-phase oil-immersed transformer uses a fully oil-filled, sealed corrugated tank. The tank's elasticity accommodates oil expansion, ensuring a permanently sealed environment. It is widely applied in various power distribution systems.

The core components of the transformer include:

Transformer Core: The magnetic circuit part, composed of laminated silicon steel sheets (0.35mm - 0.5mm thick) coated with insulating varnish or oxidized layers for inter-sheet insulation.

Transformer Windings: The electrical circuit part, consisting of primary and secondary windings made from copper or aluminum wires with high-strength insulation.

Transformer Tank: Holds the core and windings immersed in transformer oil.

The core features vertical legs (core columns), which house both high- and low-voltage windings, and horizontal yokes that close the magnetic path. The low-voltage winding is positioned closer to the core, with the high-voltage winding outside it to facilitate insulation.

Cooling is managed through oil ducts between the windings, ensuring oil circulation. For larger transformers, external radiators or cooling tubes are added to the tank.

Transformer oil serves dual functions: insulation and cooling. It improves insulation performance, protects windings from moisture, and dissipates heat through the tank walls or cooling tubes. The oil comes in grades (10#, 25#, 45#) based on freezing points, chosen according to local climates.

Performance Features of Three-Phase Oil-Immersed Transformers

1.Excellent Winding Design

The low-voltage winding uses cylindrical copper foil structures, distributing current evenly and reducing internal losses.

High-voltage windings adopt multi-layer cylindrical designs for balanced ampere-turns, minimizing leakage flux.

These designs improve efficiency and enhance short-circuit resistance by more than 30% compared to traditional structures.

2.Reliable Mechanical Structure

The core and windings are securely fastened using self-locking nuts, ensuring integrity during transport.

Transformers with this structure can withstand shocks up to 5G, ensuring safe delivery under harsh conditions.

A core-lifting-free design further enhances stability.

3.Advanced Drying and Oil Filtration Processes

Coils and cores undergo vacuum drying to eliminate moisture, enhancing insulation.

Transformer oil is vacuum-filtered and injected, removing impurities and moisture, improving its insulation by 20%.

4.Unique Tank Design

Corrugated tanks replace conventional oil conservators, compensating for oil volume changes due to temperature fluctuations.

This design reduces transformer height, saving space, and isolates oil from external air, preventing oxidation and moisture intrusion.

Insulation deterioration is reduced by over 50% compared to traditional designs.

5.Low Maintenance and Long Lifespan

No oil replacement is required during normal operation, significantly reducing maintenance costs.

These transformers can last over 30 years, about 10 years longer than traditional models, enhancing reliability and reducing overall costs.

Operating Conditions for Three-Phase Oil-Immersed Transformers

1.Three-phase oil-immersed transformers Altitude and Temperature Requirements

Suitable for operation below 1,000 meters in indoor or outdoor environments.

Maximum ambient temperature: +40°C, where efficient heat dissipation is critical.

Minimum temperature: -25°C, where components shrink, potentially affecting insulation. Corrugated tanks accommodate oil volume changes to ensure continuous operation.

The viscosity of transformer oil decreases at high temperatures, enhancing flow and cooling, but excessive heat may accelerate oil oxidation. Selecting oils with appropriate freezing points (10#, 25#, 45#) ensures functionality in cold climates.

2.Three-phase oil-immersed transformers Humidity and Environmental Conditions

The transformer should operate in areas with relative humidity below 95% to prevent insulation degradation.

Sealed tanks and capsule-type oil conservators isolate oil from moisture and dust.

Transformers should not be installed in environments with fire, explosion risks, chemical corrosion, or severe vibration. Appropriate fire prevention, corrosion resistance, and shock absorption measures are necessary for reliable operation.

Three-phase oil-immersed transformers Market Trends and Future Development

Three-phase oil-immersed transformers play a vital role in the power sector, with promising future prospects.

Rising Demand: The growing global power demand, especially in emerging markets undergoing rapid industrialization and urbanization (e.g., China and India), drives the need for power equipment, including transformers.

Technological Innovation: Advancements in insulation materials, cooling systems, and remote monitoring improve performance, efficiency, and reliability. Smart monitoring technology enables remote diagnostics and enhances power system stability and safety.

Environmental Challenges: Some regions are enforcing stricter environmental standards, prompting the development of eco-friendly transformers (e.g., fire-resistant oil-immersed models). The shift toward green technologies will increase the market share of environmentally friendly transformers.

To remain competitive, manufacturers must focus on quality, reliability, and innovation. Meeting environmental requirements and providing cost-effective, long-lasting solutions will be essential to capturing market share.

This comprehensive overview highlights the design, features, and market potential of three-phase oil-immersed transformers, offering valuable insights for stakeholders in the power sector.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri