Status and Development Trends of Dry-type Transformer Manufacturers

Dry-type transformers, as an important electrical equipment, are gradually gaining market favor due to their advantages in safety, reliability, and maintenance costs. With the global energy structure transformation and the acceleration of urbanization, the number of dry-type transformer manufacturers is gradually increasing, and their technical levels are continuously improving. This article will provide a detailed discussion on the current situation, technological development, and future trends of dry-type transformer manufacturers.

1. Basic Concept and Advantages of Dry-type Transformers

Dry-type transformers are transformers that do not use liquid insulating media, primarily relying on air for cooling and insulation. Compared with oil-immersed transformers, dry-type transformers have several notable advantages:

a. High Safety: Due to the use of air insulation, dry-type transformers eliminate the risks of leakage and fire, making them particularly suitable for high-rise buildings and critical facilities.

b. Low Maintenance Costs: Dry-type transformers do not require regular replacement of insulating oil, making maintenance relatively simple and helping to reduce operational costs.

c. Environmentally Friendly: Dry-type transformers do not contain harmful substances, complying with modern environmental protection requirements and meeting the needs of sustainable development.

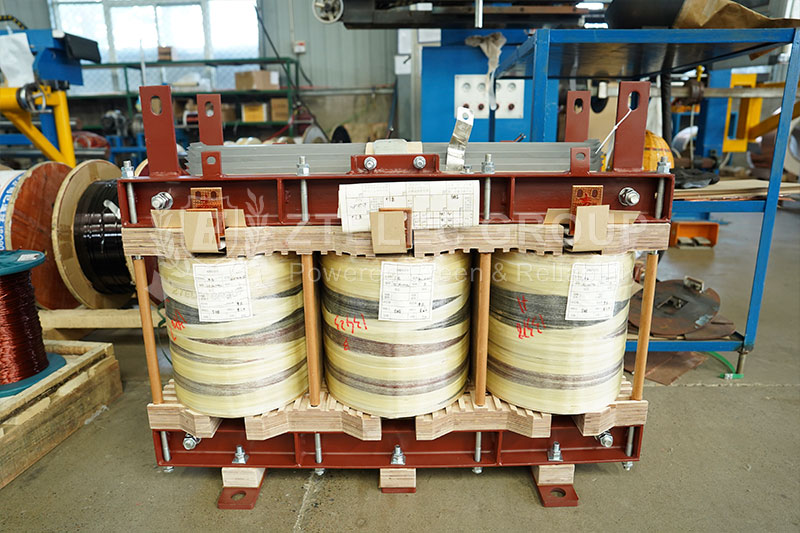

Dry-type Transformer

2. Current Situation of Dry-type Transformer Manufacturers

At present, there are numerous specialized manufacturers of dry-type transformers worldwide, each excelling in technology, production capacity, market share, and other aspects. Manufacturers from countries such as China, the United States, and Germany are at the forefront in the research and production of dry-type transformers. China’s dry-type transformer market is expanding year by year, with many local companies continuously enhancing their competitiveness by introducing, digesting, and absorbing advanced foreign technologies.

For example, some well-known domestic firms, such as Xidian and TBEA, have established complete production lines and mature technical teams, enabling them to produce high-power, high-performance dry-type transformers. Notably, these companies not only focus on product quality and performance but also actively expand into international markets to enhance brand influence.

3. Technological Development Trends

The technological advancements in dry-type transformers primarily manifest in material science, simulation technology, and intelligent manufacturing. In recent years, the development of new insulating materials has allowed for a continuous reduction in the size of dry-type transformers, significantly improving their load capacity and temperature adaptability.

In terms of simulation technology, the application of computer-aided design and numerical simulation techniques has made transformer design more scientific and accurate, effectively reducing resource waste during the trial production process. Additionally, the trend toward intelligent manufacturing has prompted dry-type transformer manufacturers to shift toward automated and digital production, enhancing production efficiency and product consistency.

4. Market Prospects and Challenges

The market prospects for dry-type transformers are broad, especially in the context of urban infrastructure construction, renewable energy applications, and the acceleration of electrification, where the demand for dry-type transformers continues to rise. However, manufacturers also face several challenges during their development:

a. Intensified Market Competition: The market potential for dry-type transformers has attracted many enterprises, leading to increasingly fierce competition among manufacturers and a serious phenomenon of product homogeneity.

b. Pressure for Technological Innovation: As technology advances, customers’ demands for the performance of dry-type transformers are rising, necessitating continuous technological research and development by manufacturers to maintain market competitiveness.

c. Strict Environmental Regulations: Countries are raising their requirements for environmental protection, and dry-type transformer manufacturers need to ensure green and environmentally friendly production and material use, which places higher demands on the operation and management of enterprises.

As an indispensable part of modern power systems, dry-type transformers and their manufacturers play an important role in the market. In the future, with continuous technological advancement and growing market demand, dry-type transformer manufacturers will face greater development opportunities. However, at the same time, enterprises must earnestly respond to the pressures of market competition and technological innovation, striving to enhance their overall competitiveness in order to find a more stable position in the new era of the power market. Through continuous innovation and high-quality products, dry-type transformer manufacturers can promote the sustainable development of the entire industry.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen