3240 epoxy fiberglass laminate sheet features

2024-09-27 16:49 | By: ZTELEC-www.ztelecgroup.com | 1585click

3240 Epoxy Fiberglass Laminate Sheet is an insulating material that mainly composed of electrical fiber glass cloth impregnated with epoxy resin and processed through drying and hot pressing. Epoxy resin refers to organic high molecular compounds containing two or more epoxy groups in their molecules, with relatively low molecular weights in most cases. The molecular structure of epoxy resin is characterized by the presence of active epoxy groups in the molecular chain, which can be located at the end, middle, or in a cyclic structure.

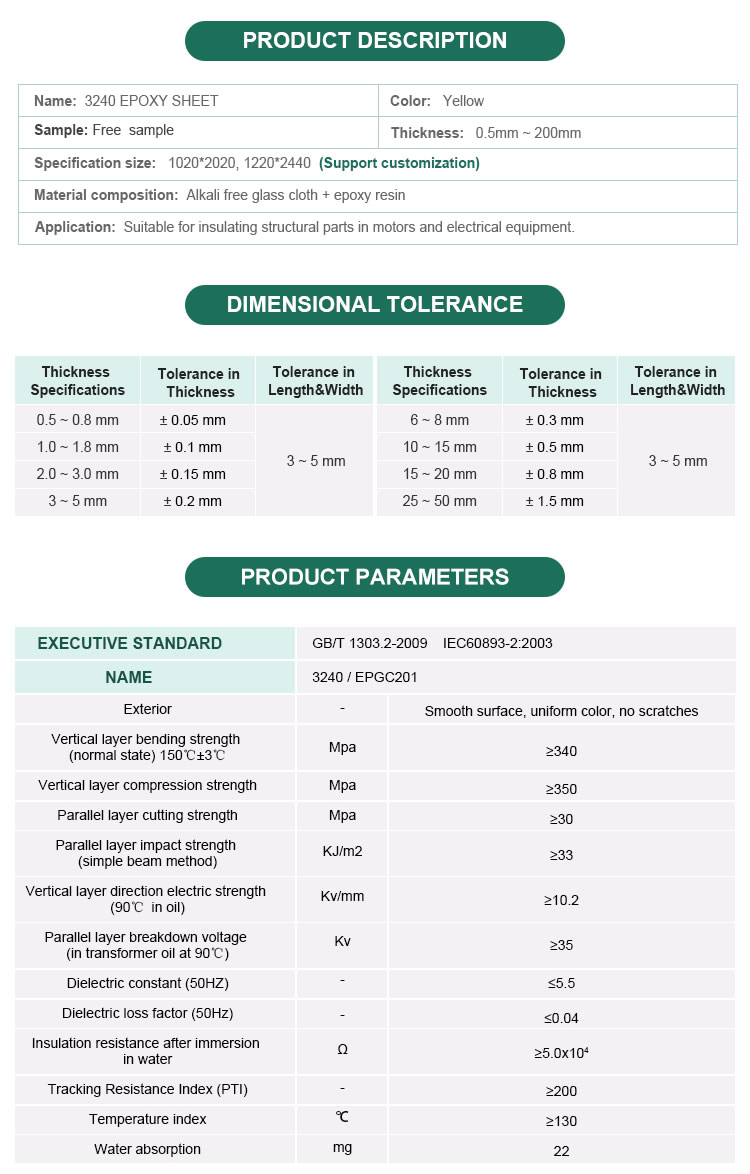

The temperature resistance grade of 3240 Epoxy Fiberglass Laminate Sheet is Class B (130°C), and colors include yellow, red, green, and black. It complies with the standard GB/T1303.1-1998 (natural color). The surface of 3240 Epoxy Fiberglass Laminate Sheet should be smooth, free of bubbles, pits, and wrinkles, with allowable defects that do not affect its use, such as scratches, indentations, stains, and minor spots. The edges should be neatly cut, and the end faces should be free from delamination and cracks. The thickness of 3240 Epoxy Fiberglass Laminate Sheet is typically 0.5 to 50mm, but can also be produced in thicknesses of 50 to 150mm as required.

Features of 3240 Epoxy Fiberglass Laminate Sheet

High mechanical strength: 3240 epoxy fiberglass laminate sheet exhibits excellent mechanical strength, making it suitable for applications requiring durability and resistance to mechanical stress.

Electrical insulation properties: This laminate sheet has high electrical insulation properties, providing protection against electrical currents and preventing short circuits.

Heat resistance: 3240 epoxy fiberglass laminate sheet is heat-resistant, able to withstand high temperatures without deformation or loss of properties, making it suitable for use in high-temperature environments.

Chemical resistance: The laminate sheet is resistant to various chemicals, ensuring its stability and performance in harsh chemical environments.

Easy to process: This material is easy to cut, drill, and shape, allowing for customization and adaptation to specific requirements in various applications.

Considering these characteristics, 3240 Epoxy Fiberglass Laminate Sheet is suitable for applications in mechanical, electrical, electronic, and electrical fields, and can be used for processing insulation components to create various insulation parts. Additionally, 3240 Epoxy Fiberglass Laminate Sheet is particularly suitable for use in humid temperature environments and transformer oil.

tags:Price of a 1600kVA 10kV Cast Resin Dry-Type Transformer35kV dry-type transformer protection10kV oil-immersed transformer110 kV oil-immersed transformerOil-Immersed Transformer Maintenance

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen