About the properties of g-10 materials

2024-08-19 11:06 | By: ZTELEC-www.ztelecgroup.com | 153click

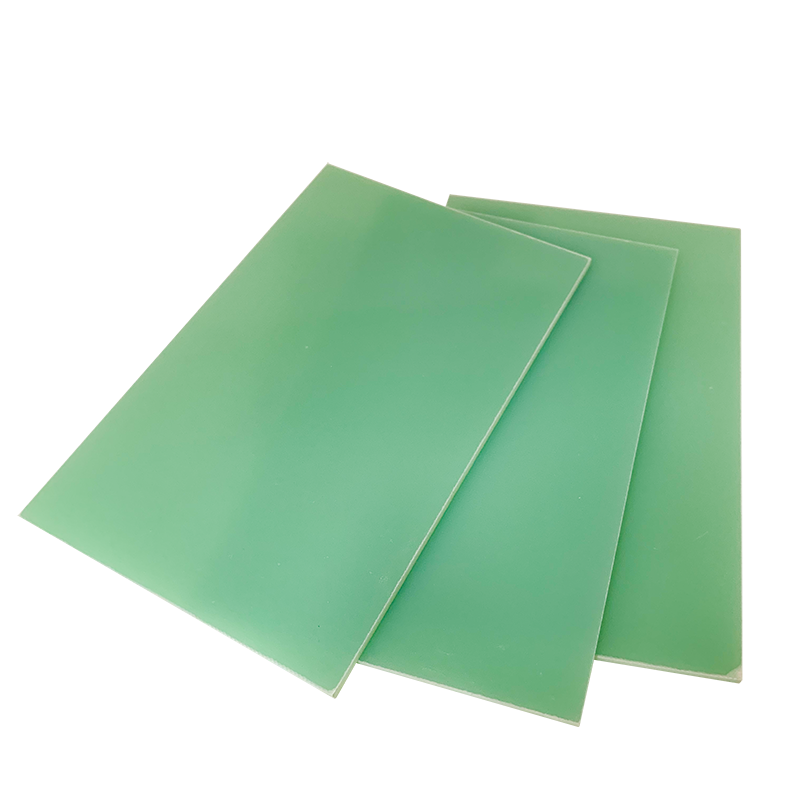

G-10 is a high-pressure fiberglass laminate, a composite material known for its strength, durability, and versatility. It is composed of layers of glass cloth soaked in epoxy resin, which are then compressed under heat until the epoxy cures. This process results in a material that is widely used across various industries due to its impressive properties.

Properties of G-10

Mechanical Strength

G-10 exhibits high tensile and flexural strength, making it resistant to stretching and deformation under applied loads. This mechanical robustness is crucial for applications where structural integrity is paramount, such as in aerospace and engineering components.

Electrical Insulation

G-10 is renowned for its excellent dielectric strength, making it a preferred choice for electrical insulation applications. Its ability to resist electrical breakdown is vital for ensuring the reliability of electronic and electrical systems. Additionally, G-10 has low moisture absorption, contributing to its stability in electrical applications.

Chemical Resistance

The material is chemically resistant, which allows it to withstand exposure to various chemicals without degrading. This property, combined with its electrical insulation capabilities, makes G-10 suitable for use in harsh environments.

Thermal Shock Resistance

G-10 can resist thermal shock, maintaining its integrity under rapid temperature changes. This makes it suitable for applications that experience extreme thermal variations.

Customization and Machinability

G-10 can be easily machined and customized to meet specific design requirements. This characteristic enhances its versatility, allowing for precision shaping and adaptation to various applications.

Applications of G-10

Electrical and Electronic Uses

Originally used in printed circuit boards, G-10's excellent electrical properties make it indispensable in electronic applications. It is commonly used as insulation material in electronic and electrical systems.

Aerospace Components

G-10 is used in aerospace engineering for components requiring a high strength-to-weight ratio and electrical insulation. Its lightweight nature contributes to fuel efficiency in aerospace structures.

Knife and Firearm Handles

G-10 is a popular material for knife handles and firearm grips due to its strength, low moisture absorption, and ease of machining. It can be textured, sanded, or polished, allowing for a wide range of aesthetic and functional customizations.

Marine and Cryogenic Applications

The material's resistance to moisture and thermal shock makes it suitable for marine applications and environments with subzero temperatures.

Safety and Environmental Considerations

While G-10 is safe to handle under normal conditions, precautions should be taken during cutting or grinding, as the dust generated can contribute to respiratory disorders. Proper ventilation and protective gear are recommended during such operations. Additionally, G-10 is not inherently flame-retardant, and in some applications, it is replaced by FR-4, which includes flame retardant additives.

In summary, G-10 is a versatile and high-performing composite material with numerous advantages, including exceptional electrical properties, chemical resistance, and high strength. These properties make it an ideal choice for a wide range of applications, from electrical components to aerospace and marine uses.

tags:insulation failure transformertransformer short circuittransformer overheatingtransformer overloadtransformer maintenance

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri