what is G11 Insulation material

2024-06-28 10:06 | By: ZTELEC-www.ztelecgroup.com | 71click

WHAT IS G11 GLASS EPOXY COMPOSITE?

G11 is a high-temperature, thermoset industrial fiberglass laminate made from filament glass cloth and an epoxy resin binder, is a fiberglass-epoxy composite material. It has the characteristics of high temperature resistance, high mechanical strength, good insulation and corrosion resistance.Applications: Commonly used in aerospace equipment, electrical systems, medical devices, and other high-performance applications.

G11 is similar to G10 but offers better performance at higher temperatures and improved insulative properties. It’s available in sheet, rod, and tube forms and can be machined using standard tools.

HOW IS G11 MADE?

G11 glass epoxy composite is manufactured through a process that involves layering glass fabric sheets and saturating them with an epoxy resin. Here’s a step-by-step overview of the process:

1.Layering: Multiple layers of glass cloth are stacked together. The glass fabric used is specifically designed for high-temperature applications.

2.Saturating: The layers of glass cloth are then saturated with a high-temperature epoxy resin, ensuring each layer is thoroughly impregnated with the resin to enhance the material’s mechanical and insulative properties.

3.Curing: The saturated layers are subjected to controlled curing under high pressure. This step is crucial as it polymerizes the resin, bonding the layers into a solid, uniform sheet.

4.Finishing: After curing, the material is cooled and can be cut or machined into various shapes and sizes, such as sheets, rods, and tubes1.

The result is a robust composite material with exceptional durability, high mechanical strength, and excellent electrical insulation properties, suitable for a wide range of high-performance applications

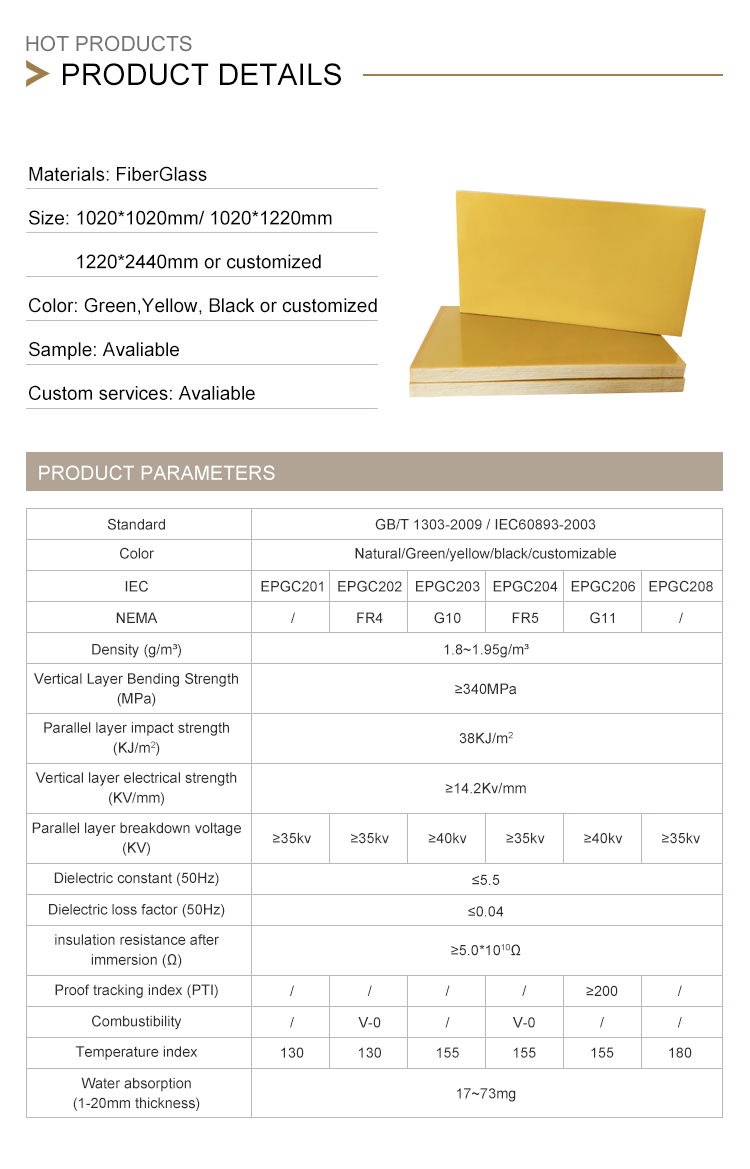

PRODUCT PARAMETERS

What are the features of g11

G11 glass epoxy composite is a high-performance material with several notable features that make it suitable for demanding applications. Here are some of the key features of G11:

High Temperature Resistance: G11 can operate continuously at temperatures up to 180°C for Class H and 150°C for Class F, making it ideal for high-temperature environments.

Mechanical Strength: It has a high tensile strength of 63,000 psi, compressive strength of 37,000 psi, and flexural strength of 75,000 psi, ensuring durability and reliability under stress.

Electrical Insulation: With excellent dielectric properties, G11 serves as an effective insulator, particularly in electrical applications.

Chemical Resistance: The material resists a variety of chemicals, which allows for its use in corrosive environments.

Low Moisture Absorption: G11 maintains its properties even in humid conditions due to its low moisture absorption.

Dimensional Stability: It exhibits low cold flow and retains its shape and size under mechanical and thermal stress.

Radiation Resistance: G11 is resistant to radiation, which is beneficial for aerospace and medical applications.

Cryogenic Serviceability: It can be used in extremely low-temperature environments, maintaining its properties in cryogenic conditions.

What are the advantages and disadvantages of G11?

G11 glass epoxy composite offers a range of advantages, particularly in high-temperature and high-performance applications. Here are some of the benefits and potential drawbacks:

Advantages:

High Temperature Resistance: G11 can withstand continuous operating temperatures up to 180°C for Class H and 150°C for Class F, which is higher than G10.

Mechanical Properties: It maintains better mechanical properties at higher temperatures compared to G10, with high tensile, compressive, and flexural strength.

Electrical Insulation: Excellent dielectric strength and low moisture absorption make it an effective insulator.

Chemical Resistance: G11 is resistant to a variety of chemicals, suitable for both wet and dry conditions.

Radiation Resistance: Suitable for aerospace and medical applications due to its resistance to radiation1.

Dimensional Stability: Exhibits low cold flow, retaining its shape under mechanical and thermal stress.

Cryogenic Serviceability: Can be used in extremely low-temperature environments, maintaining its properties in cryogenic conditions1.

Disadvantages:

Machinability: While G11 can be machined using standard tools, its unique properties can make it challenging to machine with optimal accuracy.

Cost: The high-performance features of G11 may come at a higher cost compared to other materials, which could be a consideration for budget-sensitive projects.

Availability: Custom sizes or shapes might require special ordering, and not all suppliers stock G11 in all forms, potentially leading to longer lead times.

What are the uses of G11?

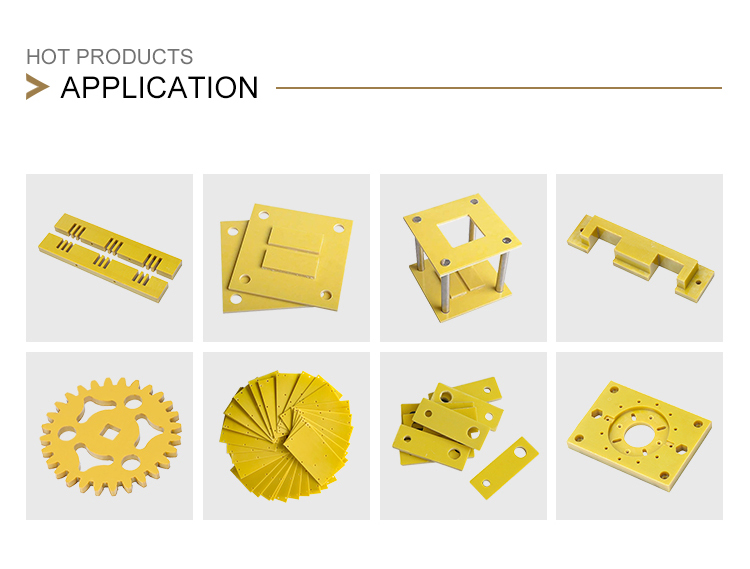

G11 glass epoxy composite is utilized in a variety of applications due to its robust properties, particularly its high temperature resistance and excellent electrical insulation. Here are some common uses of G11:

Aerospace Equipment: Due to its high strength and temperature resistance, G11 is used in components that must withstand extreme conditions.

Antenna Insulators: Its excellent dielectric properties make it suitable for insulating parts in antennas.

Cryogenic Insulation: G11’s ability to maintain its properties at very low temperatures makes it ideal for cryogenic applications.

Circuit Board Holders: The material’s dimensional stability and insulative strength are beneficial for holding and insulating circuit boards.

End Plates: In electrical equipment, G11 provides sturdy and reliable end plates.

Electrical Equipment: It is used in various electrical applications due to its high dielectric strength and chemical resistance.

Medical Diagnostic Equipment: The material’s safety and reliability are crucial in the medical field, especially for diagnostic devices.

Rocket Cases: G11’s resistance to high temperatures and mechanical stress makes it suitable for components like rocket cases.

Solder Frames: Its properties allow it to be used in solder frames, which require resistance to heat and chemicals.

How much does G11 cost?

The cost of G11 glass epoxy composite can vary depending on the supplier, the size, and the quantity of the material. For example, one source lists prices starting from $173.301. However, it’s important to note that there may be a minimum order requirement or a service charge for orders below a certain amount. For instance, some suppliers may have a minimum internet order requirement of $75.00, and orders less than this amount could be subject to a service charge of around $25.002.

To get the most accurate pricing, it’s best to contact suppliers directly or request a quote based on your specific needs, as prices can fluctuate and may be subject to discounts for bulk purchases or vary based on custom specifications.

Where to buy G11

You can purchase G11 glass epoxy composite from various suppliers that specialize in industrial laminates and composite materials. Here are a few options where you can find G11:

Polymer Plastics Company, LC: They offer G11/FR-5 glass epoxy composite laminate material, which includes continuous filament glass cloth material with an epoxy resin binder.

Sam Composites: This supplier provides a range of G11 composite products, including high-temperature resistant rigid plate-like insulation material made of alkali-free glass fiber cloth impregnated with high-temperature epoxy resin.

Professional Plastics: They have G11 glass epoxy laminate sheets and rods available, meeting various industry standards.

Trident Plastics, Inc.: You can browse their catalog for NEMA G-11 glass epoxy sheets, which include detailed specifications and properties.

It’s recommended to contact these suppliers directly or visit their ztelecgroup websites to inquire about availability, pricing, and shipping options to your location. Make sure to specify the form (sheet, rod, tube) and dimensions you require for your application.You can also contact us to submit your requirements

tags:insulation failure transformertransformer short circuittransformer overheatingtransformer overloadtransformer maintenance

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri