Polyimide film Application and principle

What is polyimide film?

Polyimide has an extremely strong molecular structure, making it a plastic with good heat resistance among thermosetting resins.

It also has excellent electrical properties such as high insulation, low dielectric constant and bulk dielectric loss, as well as chemical resistance and radiation resistance. It is an important material for electrical and electronic equipment, various industrial equipment, and aerospace fields, and its low thermal expansion coefficient can suppress dimensional errors.

Due to its adhesiveness, soldering heat resistance, and dimensional stability, it has made a great contribution to the miniaturization of products.

Application of polyimide film

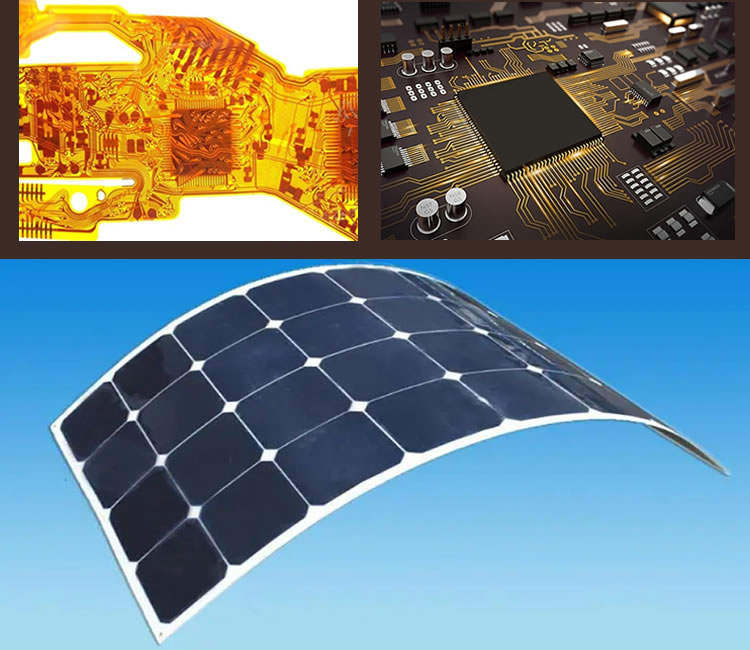

Polyimide film has a low dielectric constant and low thermal expansion coefficient, so it is used as an insulator for precision flexible printed circuit boards and motor coils. They are built into devices such as laptops and smartphones.

The color of polyimide is usually yellow or orange, but transparent polyimide film has a wide range of uses. It is used as a substrate for smart glasses, a next-generation display substrate, a substrate that utilizes transparency (such as a solar cell substrate), and a display device (such as a touch panel and a display).

Principle of polyimide film

The main chain structure of polyimide is mainly composed of aromatic rings (benzene ring and imide ring). Since there are few single bonds that can rotate freely, the conformational structure hardly changes, which means that the glass transition point and melting point become high. This is why polyimide has high heat resistance.

Many polyimide films are yellow or orange because they form charge transfer complexes within and between molecules based on the polarization of the imide ring. As an optical material, colorless and transparent polyimides are required, for example, polyimides with non-planar structures formed by intentionally generating steric hindrance by substituents, polyimides with alicyclic structures, etc.

When used as a substrate, it is important to keep the dielectric constant of the polyimide insulating film as low as possible to increase the signal speed. This can be achieved by introducing bulky linking groups in the main chain to reduce the proportion of highly polarized imide rings, or by introducing fluorine or trifluoromethyl groups as substituents.

Types of polyimide films

1. General-purpose polyimide film

General-purpose polyimide film is the most common type of polyimide film and is widely used in industrial fields. Its main feature is high heat resistance.

The heat resistance temperature of general-purpose polyimide film is usually above 200℃, which is suitable for use in high-temperature environments. It also has excellent chemical resistance and wear resistance, allowing it to withstand long-term use in various environments.

2. Ultra-high heat-resistant polyimide film

Ultra-high heat-resistant polyimide film is a film with higher heat resistance than general-purpose polyimide film. Their heat resistance temperature is generally above 300℃, and they are widely used in harsh industrial fields and aerospace industries that need to be used in high-temperature environments.

It is sometimes used as an insulating material for high-temperature parts of engines and propulsion systems of aircraft and aerospace equipment components. In addition, this film plays an important role in applications such as engines, high-temperature furnaces, and electronic equipment that require insulation and protection in high-temperature environments.

3. Transparent polyimide film

Transparent polyimide film has the same characteristics as ordinary polyimide film, but is also transparent. Ordinary polyimide film is generally opaque, while transparent polyimide film becomes transparent through special processing.

Used to make transparent parts such as automotive sensor covers, high-temperature transparent bags, and optical sensors that require transparent windows in high-temperature environments. It can also be used in fields such as semiconductor manufacturing and optical equipment.

4. Adhesive polyimide film

Adhesive-backed polyimide film is a polyimide film with an adhesive on one side. This makes it easy to apply and is particularly useful for assembling and protecting electronic devices and electrical components.

Adhesive polyimide film is used to insulate wiring, protect components, and act as a sealant, and is used in the manufacturing process of electronic devices. In addition, since it can maintain adhesion in high-temperature environments, it is a film suitable for protecting and insulating high-temperature components.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri