Fiberglass reinforced laminates for body armor

A customer recently inquired whether fiberglass laminates offered by ZTelec Group can be used to make body armor. Sure! Fiberglass reinforced laminates can be used as a structural material for bulletproof vests made of multi-layer high performance fiber composites.

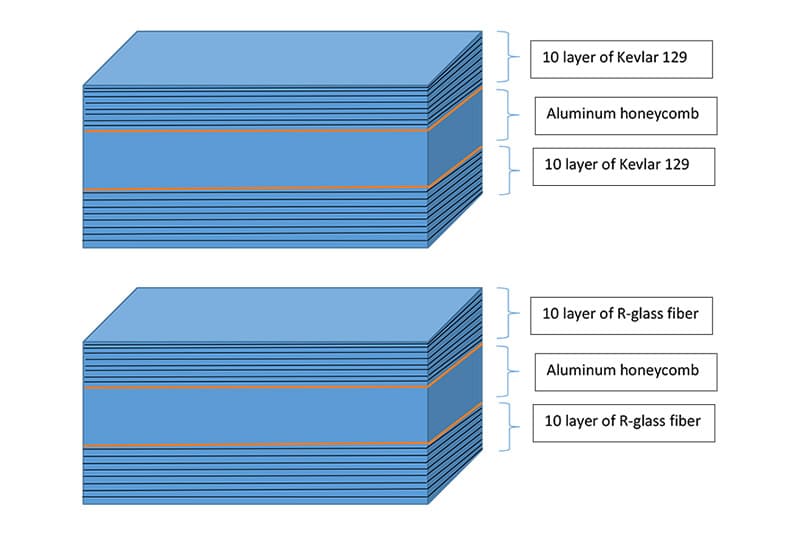

In terms of the structure of body armor, its development has undergone lots of changes from the initial rigid materials such as metal, ceramics, and high-performance composite sheets to the high-performance fibers such as aramid fiber Kevlar, ultrahigh molecular weight polyethylene (UHMWPE for short), nylon and other soft materials to this today. The bulletproof vest made from rigid materials solely is too bulky, while the soft type, although fitting the body well, but cannot prevent the impact force of weapons with sufficient initial velocity, so the more common choice is the combination of multi-layer fibers and the metal plate as the inner core. The two categories of protective layers, bonded together by hot pressed technology, can effectively prevent harm to human body. For instance, customers can refer to the following multi-layer composite structure of Kevlar, fiberglass reinforced laminates and aluminum honeycomb core or fiberglass laminates plus aluminum honeycomb core.

1. kevlar + fiberglass reinforced laminates + aluminum honeycomb + fiberglass reinforced laminates + kevlar

2. fiberglass reinforced laminates +aluminum honeycomb + layers of fiberglass reinforced laminates

As for the fiberglass reinforced material, you can use FR4 and G10, both made of electronic grade alkali-free glass fiber cloth impregnated with epoxy resin and cured by hot pressing technology. FR4 has additional flame retardant properties compared with G10, and its mechanical and electrical properties are stronger than G10. If there is a need for fire resistance, FR4 can be an ideal material.

Bulletproof vests made of multi-layer fiber composites work on the principle that when a bullet hits the vest, it first comes into contact with the multi-layer mesh structure formed by the Kevlar or fiberglass, which can "catch" the bullet fired by the gun or absorb the impact force of the blast fragments. Different layers in the fabric will also have different roles, such as to resist the speed of the bullet, to prevent sharp objects stabbing, etc. This first line of defense consumes most of the energy of the bullet and acts as a cushion. Fiberglass laminates and aluminum honeycomb core will provide further protection.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri