Paper Phenolic Sheets: An In-Depth Exploration Introduction

Phenolic Laminated Paper-Base Sheets Introduction

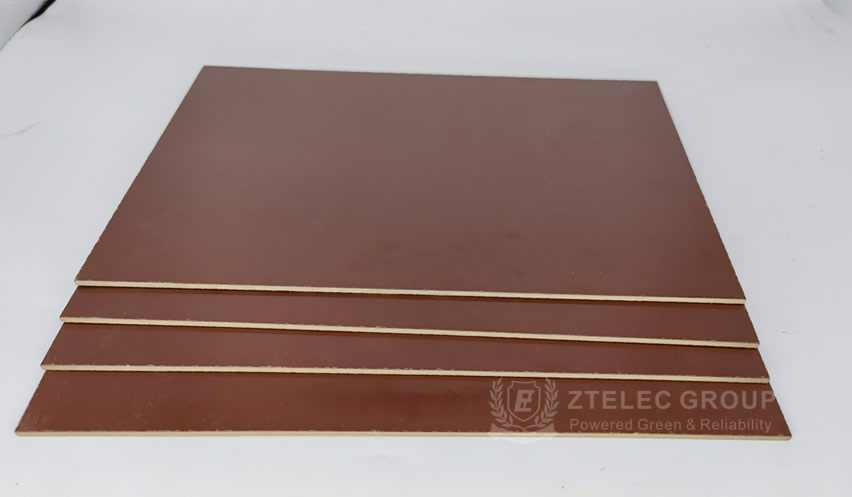

Phenolic laminated paper-base sheets, commonly referred to as phenolic laminates, are composite materials that have found extensive use in various industries due to their remarkable properties. They are engineered by impregnating layers of paper with phenolic resin and then curing the resulting structure under heat and pressure. This process creates a strong, durable, and versatile material that is particularly valued for its mechanical, thermal, and electrical properties.

Composition and Manufacturing Process

1. Raw Materials:

- Phenolic Resin: The primary component, phenolic resin, is a synthetic polymer obtained through the polymerization of phenol and formaldehyde. It is known for its excellent adhesive properties, high-temperature stability, and resistance to chemical degradation.

- Paper Layers: These can be made from various types of cellulose-based paper, which serve as the base for the laminate. The choice of paper can affect the laminate’s final properties.

2. Manufacturing Steps:

- Impregnation: The paper layers are saturated with a phenolic resin solution. The resin penetrates the fibers of the paper, ensuring thorough bonding.

- Layering: Multiple layers of impregnated paper are stacked together. The number of layers can vary based on the desired thickness and properties of the final product.

- Curing: The stacked layers are subjected to heat and pressure in a hydraulic press. This step is crucial as it activates the resin, causing it to cure and form a solid bond between the layers. The curing process usually takes place at temperatures ranging from 120°C to 180°C (248°F to 356°F) for specific time intervals, depending on the thickness and type of laminate being produced.

- Finishing: Once cured, the sheets are trimmed, sanded, or coated to meet specific requirements. Additional treatments can enhance properties like surface finish or fire resistance.

Properties of Phenolic Laminated Sheets

Phenolic laminated paper-base sheets possess a range of properties that make them suitable for various applications:

1. Mechanical Strength:

- The laminates exhibit high tensile and compressive strength, making them suitable for load-bearing applications. They resist deformation under stress and are durable even in challenging environments.

2. Thermal Stability:

- These sheets can withstand high temperatures without losing structural integrity. They typically have a continuous operating temperature of around 120°C (248°F) to 150°C (302°F), although some specialized formulations can handle even higher temperatures.

3. Chemical Resistance:

- Phenolic laminates are resistant to a variety of chemicals, including solvents, acids, and alkalis. This property makes them ideal for use in environments where exposure to harsh substances is common.

4. Electrical Insulation:

- Due to their low electrical conductivity, phenolic laminates are widely used as electrical insulation materials in applications such as circuit boards, electrical panels, and switchgear.

5. Surface Finish:

- They can be manufactured with a smooth surface finish, making them suitable for applications that require aesthetic appeal and easy cleaning.

Applications

Phenolic laminated paper-base sheets are utilized across a wide array of industries, including:

1. Electrical and Electronics:

- Insulation Boards: They are commonly used as insulating substrates in electrical components due to their excellent dielectric properties.

- Circuit Boards: The high thermal and chemical resistance makes them ideal for use in printed circuit boards (PCBs).

2. Construction:

- Countertops: Their durability and resistance to moisture make them suitable for countertops in kitchens and laboratories.

- Wall Panels: They are used in wall panels for their aesthetic qualities and durability.

3. Automotive:

- Insulating Components: In automotive applications, phenolic laminates are used in components that require high thermal resistance and electrical insulation, such as brake pads and electrical connectors.

4. Industrial Applications:

- Wear Plates: Their toughness allows them to be used as wear plates in machinery and equipment.

- Tooling and Jigs: The strength and rigidity of phenolic laminates make them suitable for making jigs and fixtures used in manufacturing processes.

Advantages and Limitations

Advantages:

- Versatility: Can be tailored to meet specific requirements through modifications in the resin, paper type, and layering.

- Cost-Effective: Compared to other high-performance materials, phenolic laminates are relatively inexpensive and widely available.

- Eco-Friendly Options: Some manufacturers are developing phenolic laminates using sustainable raw materials and processes.

Limitations:

- Moisture Absorption: While generally resistant to moisture, prolonged exposure can lead to swelling and degradation over time.

- Limited Flexibility: Compared to some plastics, phenolic laminates can be more rigid, which may limit their use in applications requiring flexibility.

- Brittleness: In certain conditions, particularly at lower temperatures, they can become brittle.

Conclusion

Phenolic laminated paper-base sheets are a crucial material in various industries, valued for their strength, thermal stability, and electrical insulation properties. Their manufacturing process allows for customization, making them suitable for a wide range of applications from electrical components to construction materials. While they have some limitations, the advantages they offer make them a preferred choice in many engineering and industrial applications. As technology continues to advance, the development of even more specialized formulations and applications for phenolic laminates is likely to emerge, further expanding their utility in modern manufacturing and design.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen