How to choose the right fr4 material

Choosing the right FR4 material is critical for the electronics industry. FR4 is a commonly used circuit board substrate material. It has excellent insulation properties and mechanical strength and is suitable for a variety of application scenarios. However, there are different types and grades of FR4 materials available in the market, so the correct selection of the right material is very important to ensure the performance and reliability of electronic products.

What is FR4 material?

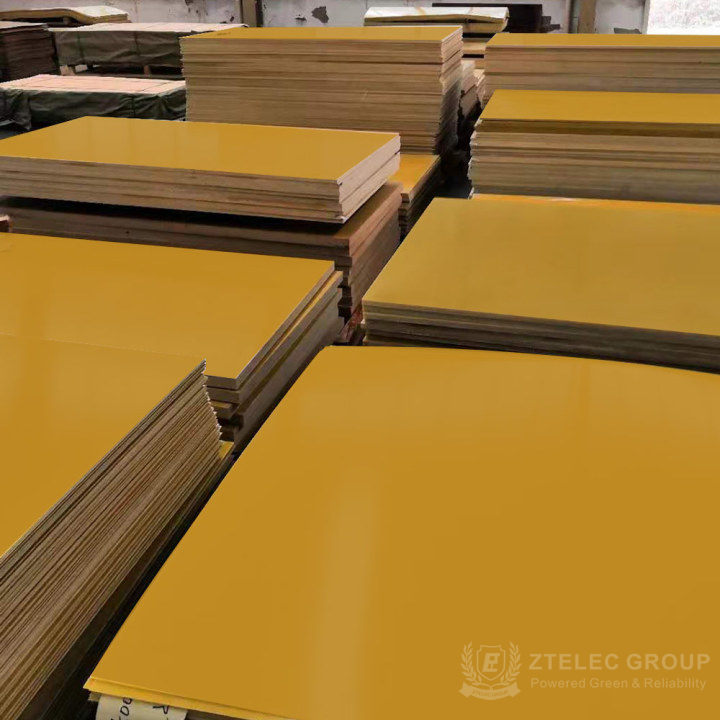

FR4 is a common composite material that is widely used in the manufacture of electronic circuit boards. It consists of fiber glass cloth and imported epoxy resin, and has high mechanical properties, dielectric properties, electrical insulation properties. The insulation class is F, and the main colors are white (primary), light green, black and yellow.

Why use FR4 material?

FR4 are electrical insulators with high dielectric strength. They also feature a high strength-to-weight ratio and are lightweight and resistant to moisture. Add this to their relative temperature resistance, and FR4 material can perform well in most environmental conditions.

How to choose right FR4 material?

First, you need to consider the application environment and requirements. Different application environments have different requirements for the properties and characteristics of FR4 materials. For example, circuit boards operating in high temperature environments need to have high thermal stability and temperature resistance, so FR4 materials with high TG values (glass transition temperature) should be selected. Circuit boards that work in humid environments need to have good moisture resistance, so FR4 materials with low moisture absorption should be selected.

Secondly, the laminated structure and thickness of the circuit board need to be considered. Different lamination structures and thicknesses have a direct impact on the performance and cost of the circuit board. Generally, more complex board lamination structures need to select FR4 materials with better lamination performance to ensure the bonding strength and reliability between board layers. In terms of thickness, it is necessary to make a reasonable choice according to the size requirements and cost constraints of the specific application scenario.

Third, the manufacturer’s reputation and quality certification need to be considered. Choosing a FR4 material manufacturer with a good reputation and reputation can ensure the quality and reliability of the selected material. At the same time, it is best to choose a manufacturer certified by a quality management system such as ISO 9001 to ensure the standardization and consistency of the production process.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen