Why Choose FR5 Epoxy Sheet for High-Temperature PCB Manufacturing?

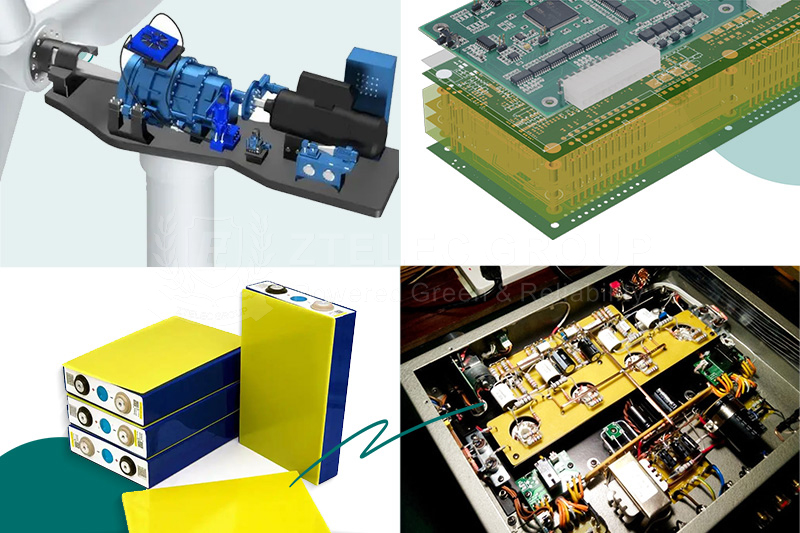

In the field of electronic manufacturing, printed circuit boards (PCBs) serve as the core and fundamental components of various electronic devices, and their importance is self-evident. With the rapid development of technology, electronic devices are continuously evolving towards miniaturization, high performance, and high power. This makes the working environment of PCBs increasingly harsh, especially the high-temperature environment has become a major challenge. Among numerous PCB materials, FR5 epoxy sheet has become the ideal choice for high-temperature PCB manufacturing due to its unique advantages. Next, we will delve into the specific reasons for choosing FR5 epoxy sheet for high-temperature PCB manufacturing.

Excellent Heat Resistance

One of the most prominent advantages of FR5 epoxy sheet is its excellent heat resistance, which is also a key factor for its popularity in high-temperature PCB manufacturing. The glass transition temperature (Tg) of this material is typically in the range of 170°C to 180°C. The glass transition temperature is an important indicator for measuring the physical and chemical stability of materials at high temperatures. When the ambient temperature is lower than Tg, the material is in a glassy state and has high rigidity and strength; when the ambient temperature is higher than Tg, the material begins to soften, and its performance will significantly decline accordingly.

In practical application scenarios, many electronic devices generate a large amount of heat during operation. For example, in industrial control equipment, automotive electronic systems, and aerospace equipment, the internal PCBs need to withstand high temperatures for a long time. FR5 epoxy sheet can maintain stable performance in these high-temperature environments without phenomena such as softening, deformation, or delamination, thus ensuring the normal operation of the circuit board and providing a solid guarantee for the stable operation of the entire electronic device. In sharp contrast, some common PCB materials are extremely prone to performance degradation problems at high temperatures, which in turn leads to circuit failures and seriously affects the reliability and service life of the equipment.

Good Mechanical Properties

In addition to excellent heat resistance, FR5 epoxy sheet also has good mechanical properties, with high tensile strength, bending strength, and impact strength. In a high-temperature environment, PCBs are often subjected to various external forces, such as vibration and impact. And FR5 epoxy sheet can effectively withstand these external forces, avoid its own damage, and ensure the integrity and reliability of the circuit board.

Take aerospace equipment as an example. During flight, the internal PCBs will suffer from strong vibration and impact. If materials with poor mechanical properties are used to manufacture PCBs, problems such as fracture and damage are very likely to occur, which in turn leads to equipment failures. With its excellent mechanical properties, FR5 epoxy sheet can ensure that the PCB still works normally in a harsh mechanical environment, providing safety for the operation of aerospace equipment.

Stable Electrical Properties

Under high-temperature conditions, FR5 epoxy sheet can still maintain stable electrical properties. It has a high volume resistivity and surface resistivity, which can effectively prevent current leakage and provide a guarantee for the safe operation of electronic devices. In some high-voltage and high-power electronic devices, such as power electronic devices, the PCB needs to withstand a relatively high voltage. If the insulation performance of the material is poor, accidents such as electric leakage and breakdown are very likely to occur, causing serious harm to the equipment and personnel.

In addition, the low dielectric constant and dielectric loss of FR5 material make the signal transmission speed on the PCB faster and the loss smaller, which helps to improve the performance of electronic devices. In high-speed digital circuits and radio frequency circuits, the requirements for the transmission quality and speed of signals are extremely high. PCBs manufactured with FR5 epoxy sheet can meet these strict requirements, effectively reducing signal delay and attenuation, and ensuring the efficient operation of electronic devices.

Excellent Manufacturing Process Compatibility

FR5 epoxy sheet has good compatibility in the manufacturing process and is easy to be processed through conventional PCB manufacturing processes such as drilling, etching, and electroplating, and can be made into PCBs of various complex shapes. During the manufacturing process, FR5 material can be well combined with conductive materials such as copper foil to ensure the connection quality and reliability of the circuit.

In the manufacturing of multi-layer PCBs, FR5 material can be used as an insulating layer, alternately stacked with multi-layer copper foil, and made into high-performance multi-layer PCBs through processes such as pressing. This multi-layer structure can improve the integration and performance of PCBs and meet the requirements of modern electronic devices for miniaturization and high performance. Moreover, the processing technology of FR5 material is mature, the production efficiency is high, and it can effectively reduce the manufacturing cost of PCBs.

- more+releated article

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-12Price of a 1600kVA 10kV Cast Resin Dry-Type Tr

- 2025-12-12How to Choose Epoxy Laminate Materials for Gen

- 2025-12-11Protection Configuration Principles for 35kV D

- 2025-12-11The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-10Application Prospects of 10kV/35kV Oil-Immerse

- 2025-12-09How to Reduce the Maintenance Cost of Oil-Imme

- 2025-12-09How to Choose the Best 110 kV Oil-Immersed Pow

- 2025-12-08Heat-Resistant DDP Insulation Paper