What are the uses of phenolic laminate sheet?

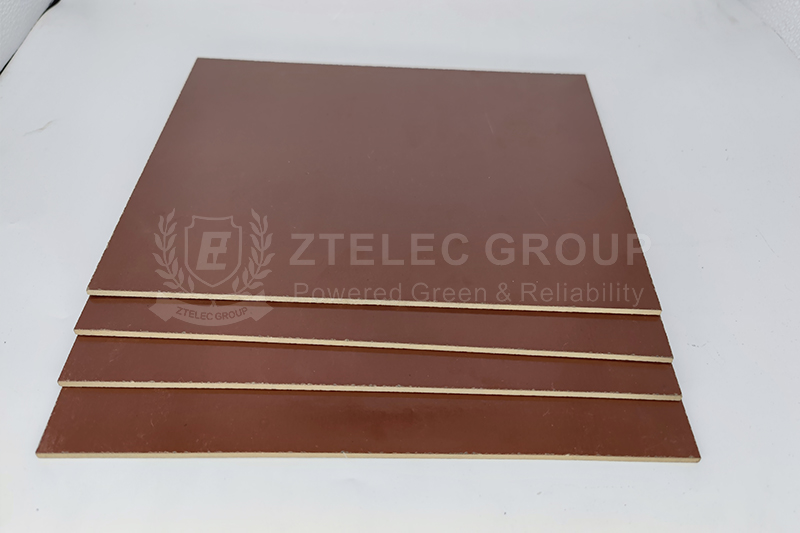

Phenolic laminate sheets are thermosetting plastic sheets composed of phenolic resin as the base material, which is impregnated with fiber materials such as paper and cotton cloth, and then pressed under high temperature and pressure. Due to its excellent mechanical properties, electrical insulation properties, heat resistance and chemical corrosion resistance, phenolic laminate sheets are widely utilized across various industrial fields.

What are the uses of phenolic laminate sheet?

1. Electrical industry

Motors and electrical equipment: Phenolic laminate sheets are widely used in electrical equipment, including motors, transformers, and switchgears. They serve as essential components, such as insulating pads, insulating partitions, and insulating supports, to ensure the safe operation of the equipment.

Electronic components: In the manufacturing of electronic components, phenolic laminate sheets are used as substrate materials, providing stable support and insulation protection for these components.

2. Mechanical industry

Mechanical parts: Phenolic laminate sheet can be used to manufacture a variety of mechanical parts, such as gears, bearing cages, and wear-resistant gaskets. Due to their excellent mechanical properties and wear resistance, these materials can significantly enhance the service life of equipment.

Mold manufacturing: In mold manufacturing, phenolic laminate sheet can be used as heating plates, fixing plates, and other components, which can withstand high temperature and high pressure without deforming.

3. Chemical industry

Corrosion-resistant equipment: In chemical production, phenolic laminate sheet is used to manufacture corrosion-resistant pipes, valves, pump bodies, and other equipment components designed to withstand the erosion caused by chemical substances.

Sealing materials: As materials such as sealing gaskets and sealing plates, phenolic laminate sheets can effectively prevent the leakage of chemical substances and ensure production safety.

4. Automobile industry

Interior parts: Phenolic laminate sheets are suitable for manufacturing automotive interior parts, such as instrument panels and door panels, etc., because of their good processing performance and beautiful appearance. This material can improve the overall quality of the vehicle.

Electrical system: In the automotive electrical system, Phenolic laminate sheets serve as insulation materials to ensure the safe and stable operation of the electrical system.

Advantages of phenolic laminate sheets

Excellent insulation performance: Phenolic laminate sheets have extremely high volume resistivity and surface resistivity, which can effectively prevent current leakage and ensure the safe operation of electrical equipment.

Good mechanical properties: It possesses high strength and hardness, excellent wear resistance, and the ability to withstand large mechanical loads without deformation or damage.

Excellent heat resistance: It can maintain stable performance in high-temperature environments, with a long-term usage temperature exceeding 120°C. It can also withstand even higher temperatures for short durations.

Excellent chemical corrosion resistance: It has good resistance to various chemicals, including acids, alkalis, and salts, making it suitable for use in harsh chemical environments.

Good processing performance: It is easy to cut, drill, mill, and perform other mechanical processing, allowing for the creation of products in various shapes and sizes as needed.

High cost-effectiveness: Compared with other high-performance materials, phenolic laminate sheets are relatively inexpensive, have a long service life, and require minimal maintenance.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri