What is the difference between FR4 and polyimide?

FR4 and polyimide (PI) are two high-performance materials widely used in the electronics industry. Each has unique properties and application areas.

What is the difference between FR4 and polyimide?

1. Material composition

FR4 is mainly composed of glass fiber cloth and epoxy resin. The glass fiber cloth provides good mechanical strength, while the epoxy resin acts as a binder to bond the glass fiber cloth together to form a strong composite material.

FR4 has excellent mechanical properties, electrical insulation properties and chemical stability due to its combination of glass fiber and epoxy resin.

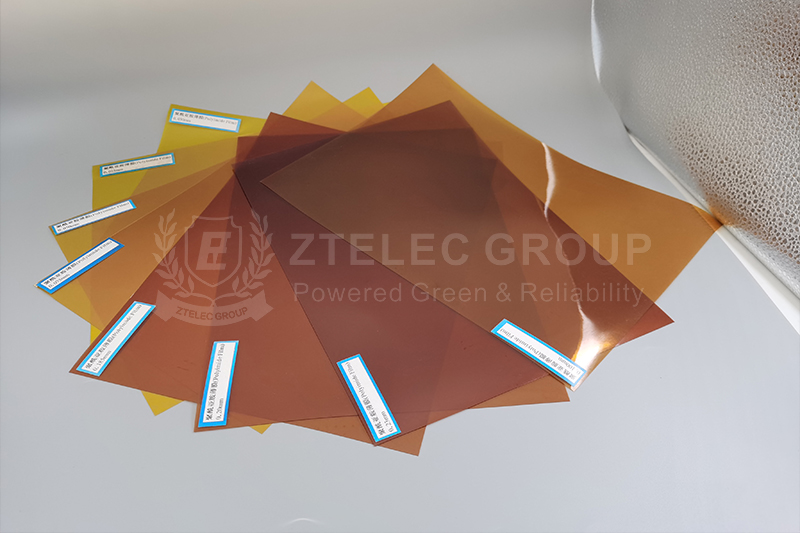

Polyimide is a type of polymer with an imide ring structure, and is usually made by polycondensation of dianhydride and diamine. Its molecular chain contains a large number of aromatic rings and imide bonds, which give the material unique properties.

Polyimide has extremely high heat resistance, good mechanical properties, excellent electrical insulation properties and chemical stability.

2. Application scenarios

FR4 is widely used in consumer electronics (such as mobile phones, computers), communication equipment, home appliances and general industrial applications. Due to its low cost, it is suitable for large-scale production.

Polyimide is suitable for flexible circuit boards, aerospace, medical electronic equipment and high-density interconnection circuit boards. The high temperature resistance and mechanical properties of polyimide make it perform well in extreme environments.

3. Comparison of advantages and disadvantages

FR4 is a flame-retardant epoxy resin composite material widely used in PCB manufacturing. Its main advantages include:

Cost-effectiveness: FR-4 is one of the most affordable options among all materials and is suitable for large-scaleproduction.

Mechanical strength: It has good bending and tensile resistance.

Electrical properties: The stable dielectric constant and low dielectric loss make it suitable for most applications.

Thermal stability: It can withstand soldering temperatures up to 260°C.

However, the disadvantages of FR-4 are its low thermal conductivity and high water absorption, which may affect its performance in high-frequency and high-temperature applications.

Polyimide (PI) is a high-performance plastic that is often used in flexible circuits and high-temperature applications. Its advantages include:

Thermal stability: It is able to operate at temperatures up to 300°C. It is suitable for applications that require long-term high-temperature operation.

Flexibility: It can be made into flexible circuit boards. It is suitable for applications with limited space or requiring bending.

Chemical resistance: It has good resistance to many chemicals.

However, the higher cost of polyimide and the difficulty of processing may limit its use in some applications.

As two important electronic materials, FR4 and polyimide each have unique performance characteristics and application areas. In practical applications, it is necessary to select appropriate materials according to specific needs and scenarios to achieve the best performance and cost-effectiveness. With the continuous advancement of science and technology, the performance and application areas of FR4 and polyimide will continue to expand and improve.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri