product description

Overview

The American-style pad-mounted transformer is a type of transformer that combines high-voltage load switches, plug-in fuses, backup protection fuses, the transformer body, and no-load switches within a sealed oil tank, using transformer oil as the insulating medium. The high-voltage circuit and transformer body are assembled inside the oil tank, with high-voltage circuit input and operations conducted on the high-voltage side. The low-voltage circuit typically consists of low-voltage circuit breakers, current transformers, and metering instruments, installed in the low-voltage compartment.

Key Attibutes

Name:Pad mounted transformer

Type : Oil immersed type

Application: Power distribution system transformer

Altitude above seal level: less than 1000masl ( More 1000masl,customizable)

Ambient temperature : -25℃~+40℃ (other customizable)

Other Attibutes:

Input voltage : 6kV,10kV, 11kV, 13.8kV,14.2kV, 20kV,22.9kV, 30kV, 35kV

Output voltage: 220V, 380V,400V,415V,440V,480V,600V

Rated capacity :50kVA-2000kVA

Phase:Three

Frequency:50Hz/60Hz

Model number:ZGS

Coil number :2

Coil structure : layer Coil

Coil material: Copper/ Aluminum

Cool way: ONAN

Iron core material: Silicon steel/ AMORPHOUS

HV bushing layout :Loop feed/ Radial feed

Standard : IEC60076/IEC 61330/IEEE C57.

Warranty: 2 Years

Composition

Oil immersed transformer

The Oil immersed transformer design is fundamentally consistent with conventional Oil immersed transformer design principles. The core material can be high-permeability silicon steel or amorphous alloy, and the core structure can be laminated or wound. The windings can be made of copper wire or copper foil.

High-Voltage System and Output Methods

The high-voltage system wiring methods include ring network type, terminal type, and terminal dual-circuit type. The ring network type features “one input, two outputs”: one power input, one output from the transformer’s low-voltage side, and another leading to another transformer or electrical device, providing power to the low-voltage side of another transformer or other equipment. The terminal type features “one input, one output”: one power input and one output from the transformer’s low-voltage side. The terminal dual-circuit type features “one input, one output, one backup”: one power input, one output from the transformer’s low-voltage side, and one backup power supply, which provides power in case of a main power supply failure.

Elbow Bushing (Elbow Cable Plug)

The high-voltage input of the combination transformer is achieved through underground cables using elbow-type cable heads, which consist of three parts: the elbow connector, load socket, and bushing sleeve. The elbow connector comes in single-pass and double-pass types. The single-pass type connects directly to the cable and the high-voltage grid, while the double-pass type connects one end to a lightning arrester and the other to a voltage source.

Lightning Arrester

The lightning arrester primarily serves as protection against lightning strikes and comes in internal and external types. The internal type is placed inside the oil tank at the high-voltage output for protection.

Other Components

No-load switches, oil level gauges, pressure gauges, temperature gauges, pressure relief valves, and other components. Additional components such as low-voltage air circuit breakers, secondary-side metering, and compensation devices can be installed as needed. The transformer’s fuses, multi-position ring network load switches, and no-load tap changers are installed as components inside the oil tank, allowing easy replacement of fuses or operation of load switches to change the transformer’s operating conditions. The high-voltage side is powered by load-break elbow-type cables, and the low-voltage output compartment is installed outside the tank, with space for additional protective devices and instruments as required. All live parts are enclosed within the oil tank, with no exposed live components.

Protection System

The American-style pad-mounted transformer protection system uses high-voltage current-limiting fuses and overload protection fuses in series for high-voltage protection, and low-voltage air circuit breakers for overload and short-circuit protection in the low-voltage circuit. The plug-in fuse (overload protection fuse) has excellent tolerance to transformer surges and is primarily used to protect the transformer during overloads and low-voltage short circuits. The backup protection fuse (high-voltage current-limiting fuse) can safely interrupt all expected currents that could cause melting and is mainly used to protect the transformer and distribution system during internal faults.

Standards Referenced:

IEC 60076: General requirements for power transformers

IEC 61330: Safety standard for high/low voltage prefabricated substations

IEEE C57.: General requirements covering the safety and performance of liquid-immersed distribution, power and regulator transformers.

Basic Parameters and Requirements

Operating Environment

1. Climate Environment

Altitude: For transformers used at altitudes of 1000m and below, altitude effects need not be considered. For altitudes above 1000m, the effects of thinner air on transformer cooling and external insulation dielectric stability must be considered. Temperature rise limits should be adjusted: for every 400m above 1000m, reduce by 1K.

High-Voltage Switchgear: Suitable for altitudes up to 1000m; for higher altitudes, refer to GB/T11022.

Low-Voltage Switchgear: Suitable for altitudes up to 2000m; for higher altitudes, refer to GB/T7251.1.

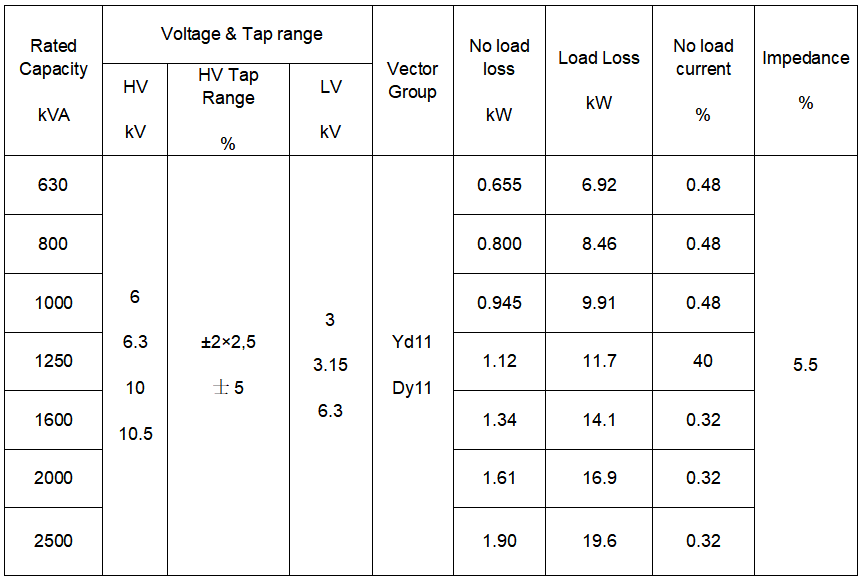

Technical parameter:

Warehouse&Package